- Ku Wiśle 7, 00-707 Warsaw

- +48 787 783 590

- biuro@interprocess.pl

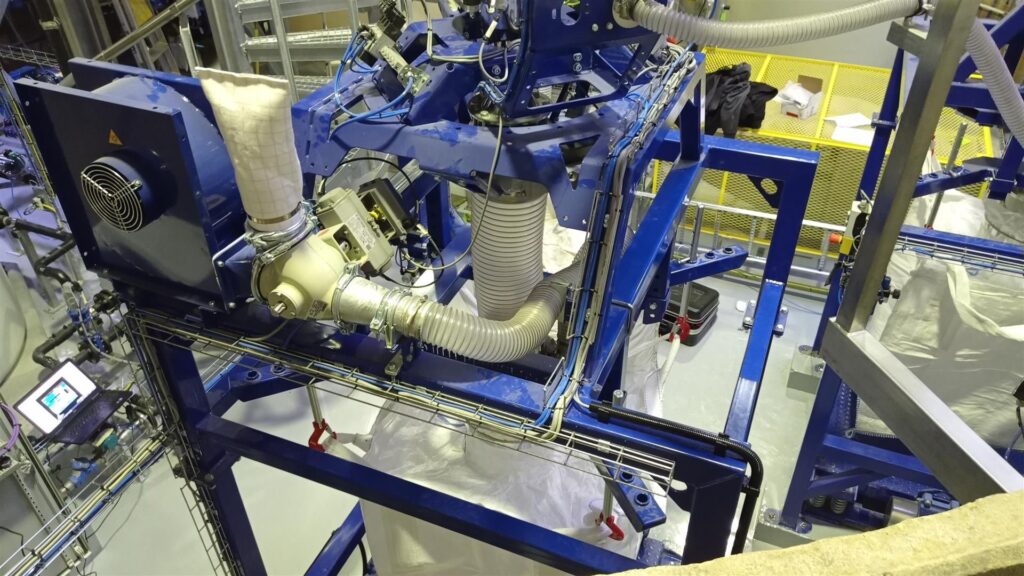

Big-bag filling systems have long ceased to be the part of the production line that generates the most dust.

In our latest project for a customer from the chemical industry in Norway, we used several interesting solutions to make the loading of bags safe, accurate and convenient for operators:

– two filling stations working alternately,

– inflatable seals for perfect sealing of the spout of the bags,

– vacuum (vacuum) transport for safe and clean handling of bulk material,

– accurate summing scales installed on pneumatic transport receivers,

– system of preforming compressed bags with a blower,

– vibrating compactors that reduce the volume of material in the bag and allow for more efficient use.

– two-channel Flex controller, equipped with a touch screen and Ethernet/Profibus communication, to control dosing at two charging stations.