- InterProcess Sp. z o.o.

What Is Pneumatic Vacuum Conveying of Bulk Materials?

Vacuum conveying of bulk materials is the process of transferring dry materials, such as powders or granules, using suction. Most vacuum conveying systems transfer products to a vacuum receiver based on a specific time, volume, or weight. At the end of the time sequence or after the appropriate amount of bulk material has been obtained, the discharge valve opens and the conveyed material can be discharged into the receiver.

When connected to a vacuum generator and a material intake point, the pneumatic receiver forms a vacuum transport system. The bulk material is transported through a network of pipes from the material intake point (e.g., pneumatic transport hopper, suction lance) to the pneumatic receiver.

Vacuum transport systems for conveying bulk materials have many advantages that make them popular in various industries, including food, pharmaceutical, chemical, and others.

What Are the Advantages of Such a System?

1. Hermeticity and Cleanliness of the Process

- Transport takes place in a closed system, which minimizes dust emissions into the environment.

- It protects the product from external contamination (important, for example, in the pharmaceutical or food industries).

- It facilitates the maintenance of hygienic conditions and compliance with sanitary requirements.

2. Safety for Operators and the Environment

- No dust means less risk to employee health.

- Reduced risk of dust explosion, especially when appropriate safety measures are in place (Ex zones).

3. Flexibility and Ease of Integration

- Possibility of routing the installation in hard-to-reach places (e.g., through walls, under the ceiling).

- Ease of expansion or modification of the system (e.g., adding diverters, elbows, filters).

- Possibility of transport on multiple levels (horizontal and vertical).

4. Automation and Low Labor Costs

- Vacuum systems can be easily integrated into automated production lines.

- They reduce the need for manual loading/unloading of materials.

- Less personnel and maintenance required.

5. Gentle Handling of the Product

- Vacuum transport (especially at the right speed and with elements such as gentle elbows) can be gentler on fragile or damage-prone materials (e.g., granules, powders).

6. Space Saving

- Transport pipelines take up less space than, for example, belt conveyors.

- Can be installed above existing equipment.

7. Easy Cleaning and Maintenance

- The systems are equipped with features that allow for easy and quick cleaning.

- Easy access to filter elements and removable components.

What Does Such a System Look Like?

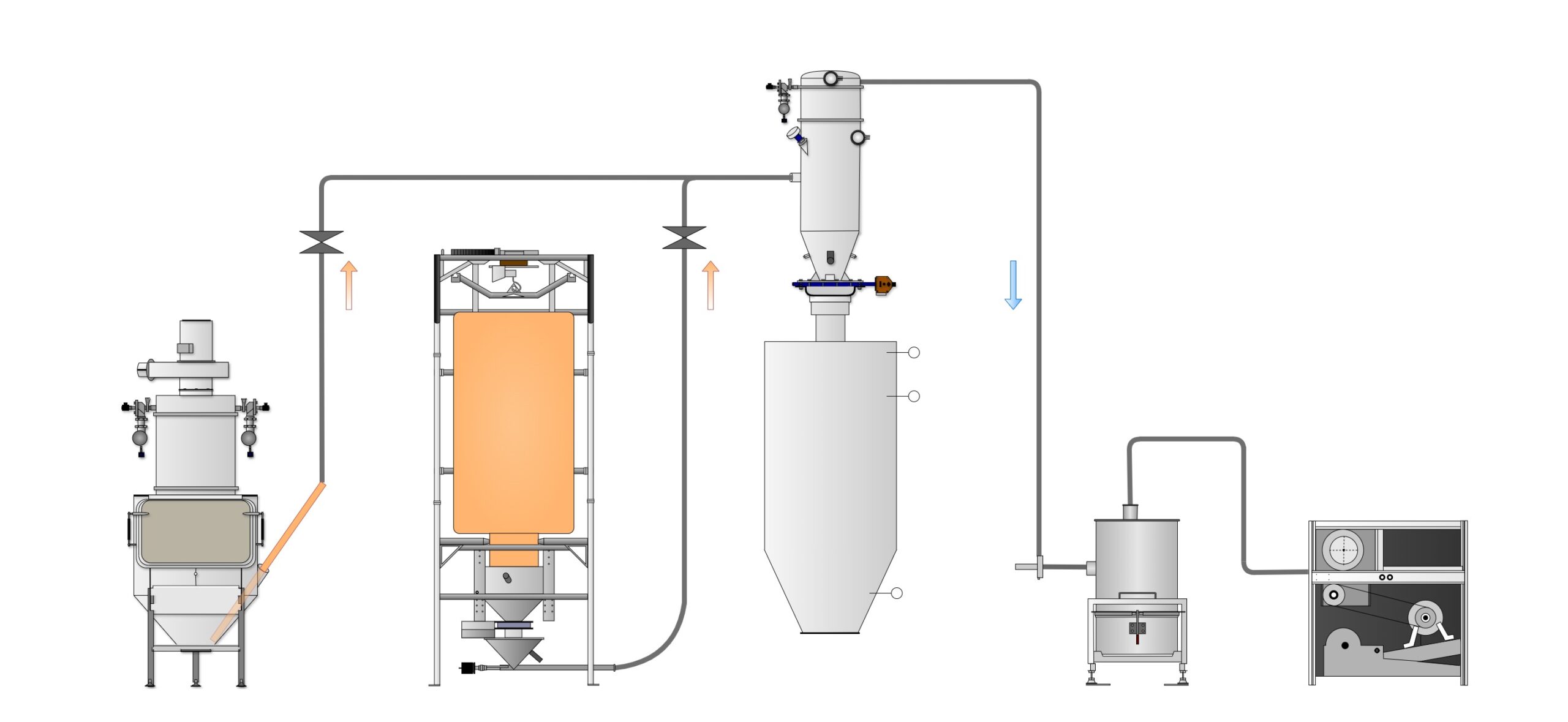

Here is an example diagram of an installation with two loading points (from the STB bag unloading station and the BSB Big-Bag unloading station) and one material discharge point (to the buffer tank). The transport receiving pipelines are connected into one, and the material is fed into a special receiver, from which the air is filtered and sucked out by a vacuum generator.

How Can We Help You?

First of all, we can analyze the possibility of applying this solution in your application and determine the value of the investment. To do this, we will ask you to briefly describe the application, material, and transfer performance, for example, by contacting us using the questionnaire below. It may be helpful to fill out the questionnaire on this page and send it to us by email. If you do not know the answers to some questions, simply leave them blank for now. With this data, we will be able to accurately check whether this type of solution can be used in your case and precisely calculate the purchase price.