- Ku Wiśle 7, 00-707 Warsaw

- +48 787 783 590

- biuro@interprocess.pl

Gravimetric screw feeders

Regardless of whether you are interested in feeding a fixed amount of material or if your process requires constant flow, we have a solution for you. Differential feeders operating in loss-in-weight mode are an interesting solution in the flow range 0,5 ÷ 30 000 [kg/h]. These are the most economical solutions, among gravimetric screw feeders, and their design ensures easy cleaning and long-lasting work.

The first step is to define material parameters, such as: grain size, bulk density, moisture, bulk angle and the required portion in the desired time interval or the required mass flow. Thanks to the information received from you, depending on the kind of material, we select the type of feeder.

The weighing system consists of a rigid platform based on smaller units on 1 or 2 single point load cells or on 3 beam load cells. In case of larger models, the scale is built on a special frame and consists of two single point sensors. This design eliminates the risk of swaying and high torque. All sensors are made of stainless steel and have a degree of protection IP68 / IP69K. Each scale is secured against overload and has transport security.

Offer

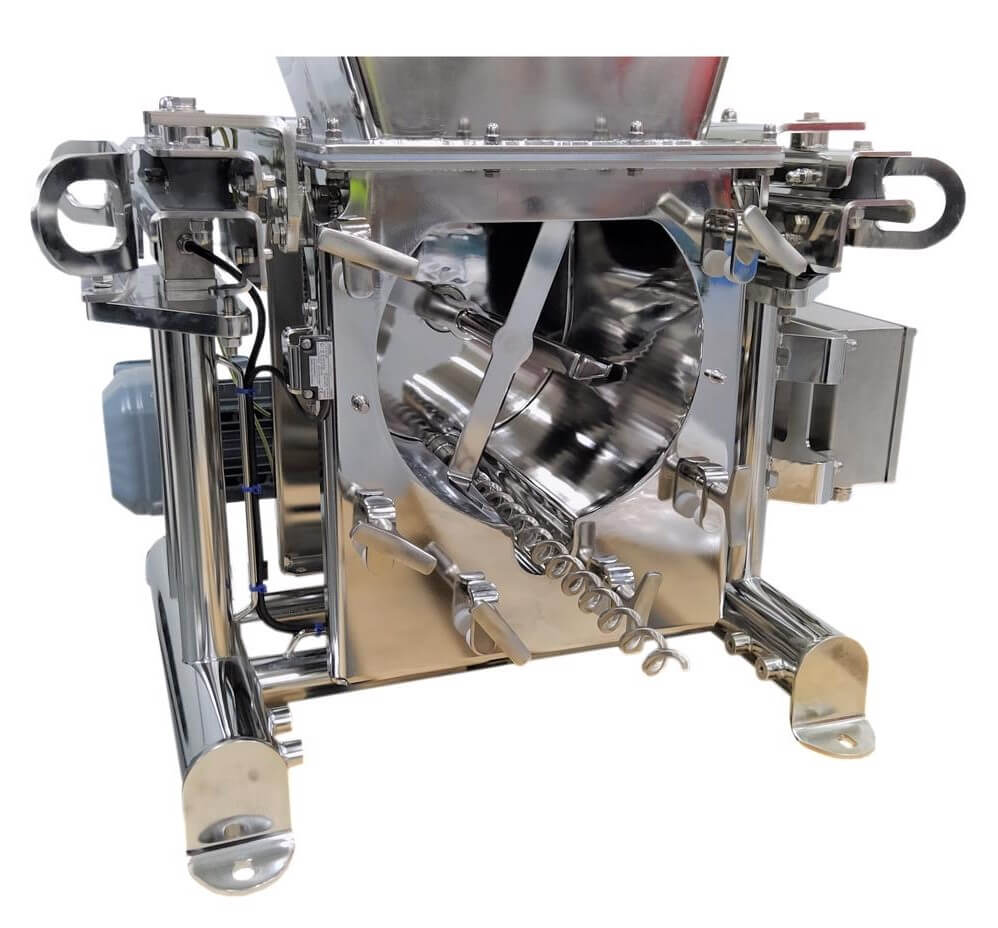

DSL(35-75-150) G

The gravimetric screw feeder DSL G is able to feed bulk products of various parameters, even difficult-flowing, rat-holing and cohesive. It consists of a main chamber, a horizontal agitator, a precise scale and a container. It generates material flow thanks to the rotating screw, supported by the horizontal agitator, which ensures full filling of the dosing element and protects the product against bridging. Typical bunkers with steep wall geometry enable a reliable flow of the dosed products. The DSL G feeder can be equipped with dosing elements with center rod or spiral (helix). Thanks to this, it is perfect for applications where difficult materials must be fed – from single-micrometer grain size dust to large granulates and pellets.

Even in the standard version, the feeder is suitable for use in the food industry. For more demanding customers, we offer a special hygienic execution. The feeder then has a special design, and thanks to the quick access to the internal chamber of the device and the open-frame structure, the device is extremely easy to keep clean. Continuous welds, grinding the interior to a roughness of Ra <0.8um, ensure even greater production safety.

Applications:

- bulk materials of various types – both well- and hard-flowing, easily aerated, with a tendency to uncontrolled flow or clumping.

Specification:

- continuous dosing – accuracy and repeatability typically <0.5% of setpoint; dosing error in batch mode depending on the range of the used load cells,

- 3 basic versions of DSL35G, DSL75G and DSL150G with different pitch and diameter of the dosing elements,

- capacity of 0.5 to 30,000 [kg / h], with the operating range of a single device min/max = 1/10

- available dosing elements (screws, spirals) with diameters from 18 to 150 [mm],

- different hopper capacities, depending on the flow,

- agitator prevents bridging of the loose product,

- for materials that are particularly difficult to dose, the possibility of installing an additional, vertical agitator,

- elements in contact with the material made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L), others are powder coated or stainless (supporting frame),

- execution

- internal surface: polished sheet, continuous welds,outer surface: blasting with glass granules or electropolishing, spot or continuous welds,

- optional hygienic design: continuous internal and external welds, ground surfaces in contact with the material (Ra <0.8), ground welds, special design,

- the device can be refilled automatically or manually.

Download:

Hygienic execution according to EHEDG guidelines

Even in the standard version, our feeders are suitable for use in the food industry. The materials used in contact with the product are FDA approved or are made of stainless steel.

For more demanding customers, we offer a special hygienic version of our device in accordance with the recommendations of the EHEDG organization. The device then has a differently designed structure, both of the feeder’s chamber and the support frame. Thanks to the quick and safe access to the interior and the more open frame, it is extremely easy to clean the device inside. Both the dosing element and the agitator can be quickly disassembled for cleaning or replacement. 316L acid-resistant steel and additionally ground inside surfaces and welds to roughness Ra <0.8 µm ensure even greater food production safety. The feeder uses aseptic motors (not applicable to explosion-proof versions), which are easy to clean due to the lack of ribbing and fan.

Explosion-risk zones

Explosion hazard zones are marked out in many production plants. Our feeders can also be delivered with an appropriate certificate in an intrinsically safe version, in accordance with the standards harmonized with the ATEX Directive. In devices such as appropriate components are then used, and the continuity of equipotential bonding guarantees proper discharge of electric charges.

Our engineers will be happy to advise you on how to install the feeder in the production line so that it functions properly and safely over many years of use.