- InterProcess Sp. z o.o.

Volumetric screw feeders

Volumetric screw feeders control flow by measuring a constant volume over time by changing the speed of the feeding element. In screw feeders, this is the rotational speed of the screw with a guide pin or spiral. Unlike gravimetric feeders, volumetric feeders do not have feedback in the form of a scale. These types of devices are the most economical solution for feeding bulk materials in continuous or batch mode.

Offer

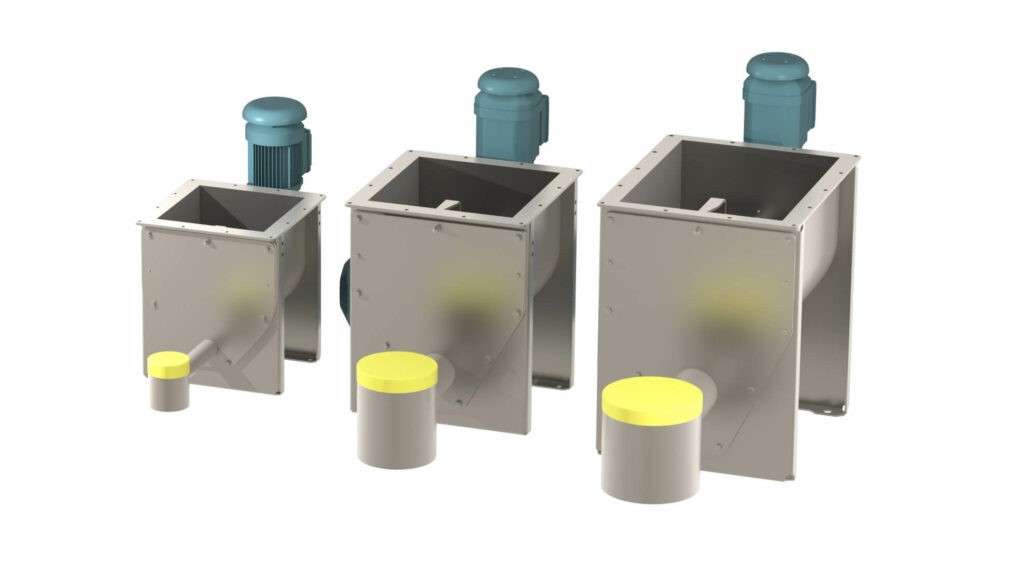

Volumetric screw feeders, model DSL(35-75-150) V

The DSL V series volumetric feeder is a universal solution that allows you to dose loose materials with a given feed rate. It can be used to feed materials with different characteristics and grain sizes.

The DSL V feeder can be an autonomous continuous dosing system and part of a portion preparation system. The construction made entirely of stainless steel, polished inside is equipped with a horizontal agitator driven by a separate electric motor. Thanks to this solution the bulk material is constantly moved and evenly fills the feeding tool in the form of a full screw (screw with center rod) or spiral screw (screw without center rod). This applies in particular to hard-flowing materials with a tendency to clumping and bridging. Feedeng tools with different diameter and pitch can be freely changed to increase the feed rate.

Applications:

- bulk materials of various types – both well- and hard-flowing, easily aerated, with a tendency to uncontrolled flow or clumping.

Specification:

- the maximum feed error after the calibration +/- 2..3%,

- horizontal agitator mixing material and filling the screw,

- feed rate from 0,5 to 30 000 [l/h],

- inlet dimensions 250×250 [mm], 350×350 [mm] or 450×400 [mm],

- feeding tools: screw or spiral, size from ∅18 [mm] to ∅152 [mm],

- easy disassembly of the screw and agitator,

- can be placed under the hopper or BIG-BAG emptying station,

- stainless steel 1.4301 (AISI 304) or 1.4404 (AISI316L),

- standard performance of the external surface: blasting with glass granulate, continuous internal welds,

- optional hygienic version, surface as well as welds ground and electropolished.

Download:

Do you need a feeder?

Contact us and our engineers will prepare the optimal solution tailored to your process. We offer the possibility of testing your material on our device.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7