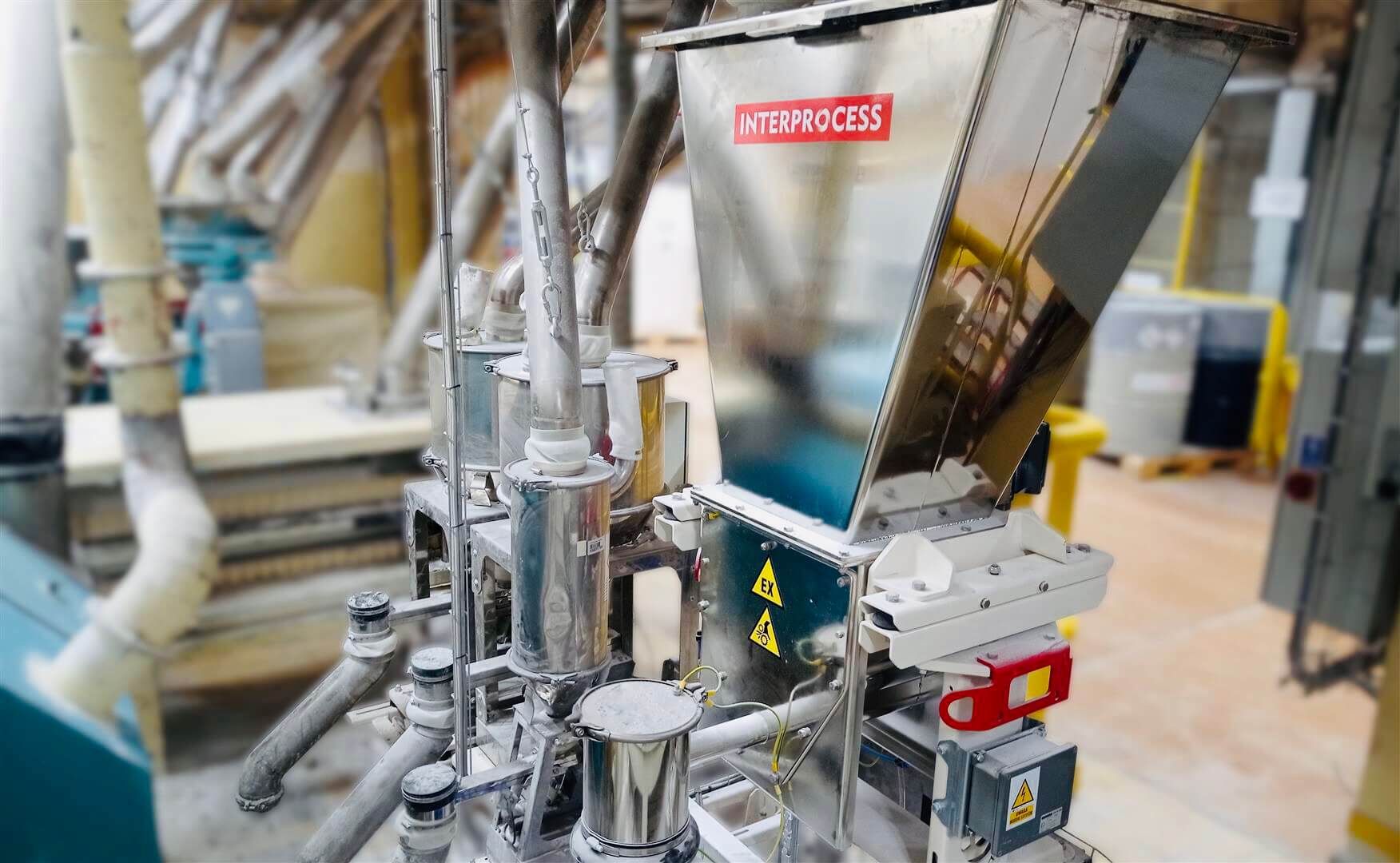

- InterProcess Sp. z o.o.

Dosing in the Handling of Bulk Materials

Dosing poses many problems when processing bulk materials. Their characteristics and behavior vary and depend on their physicochemical properties and flow rate. Key parameters include bulk density, grain size and type, tendency to clump, cohesion, adhesion, and hygroscopicity. There is no universal method for dosing every material. However, by using different solutions and options, we can accurately dose even materials that are theoretically difficult to feed. Our offer includes screw, belt, and vibratory feeders.

Continuous Mode vs. Batch Mode

Continuous production and dosing involve the uninterrupted flow of raw materials and product manufacturing. The process continues without stops, which allows for high efficiency and stability of the final product parameters. Batch mode, on the other hand, involves production in specific batches – raw materials are dosed and processed in portions, which facilitates quality control and allows for easier recipe changes, but is less time-efficient. Continuous mode is suitable for large, repetitive production runs, while batch mode is suitable for smaller series or products with variable compositions.

What Are Volumetric and Gravimetric Dosing?

Volumetric dosing involves measuring material based on its volume. Volumetric dosers work by filling a specific space with material and releasing it in a specific portion. In the case of screw feeders, the speed of rotation of the screw with a guide pin or spiral determines the capacity of the device, while in the case of belt feeders, the speed of the belt is important.

Vibrating gravimetric feeders calculate the loss in weight of the bulk product in their hopper on an ongoing basis during feeding (loss-in-weight). Thanks to fast control systems and accurate strain gauge sensors, a precise amount of material is delivered. They can operate in continuous mode (maintaining a set flow rate) or in batch mode (batching, portion feeding).

How To Choose the Right Solution?

For small and medium capacities, and in particular for materials that are more difficult to dose, the most versatile choice is usually to use DSL screw feeders. These devices can have screws with special dimensions and designs to suit the requirements of the application. An additional agitator mounted inside prevents material blockages, helps with agitation, and ensures that the screw is filled to a constant level.

We treat fragile and easily damaged materials with care. For them, the most reliable choice seems to be the DVC vibratory feeder or the DTU belt feeder. For work in difficult conditions (e.g., cement, chemical, and lime industries) and, above all, at very high capacities, the DTC belt feeder is ideal.

Of course, there are many more exceptions and nuances, which is why the key to choosing the right solution is to rely on our team of engineers.

How Can We Help You?

First of all, we can analyze the possibility of applying these solutions in your application and determine the value of the investment. To do this, we will ask you to briefly describe the application, material, manufacturing standard, and other key details, for example, by contacting us using the questionnaire below. It may be helpful to fill out the questionnaire on the product page: DSL V series volumetric screw feeders, DSL G series gravimetric screw feeders, DVC vibratory feeders or DTU and DTC belt feeders and send it to us by email. If you do not know the answers to some questions, simply leave them blank for now. With this data, we will be able to accurately check whether this type of solution can be used in your case and precisely calculate the purchase price.