- InterProcess Sp. z o.o.

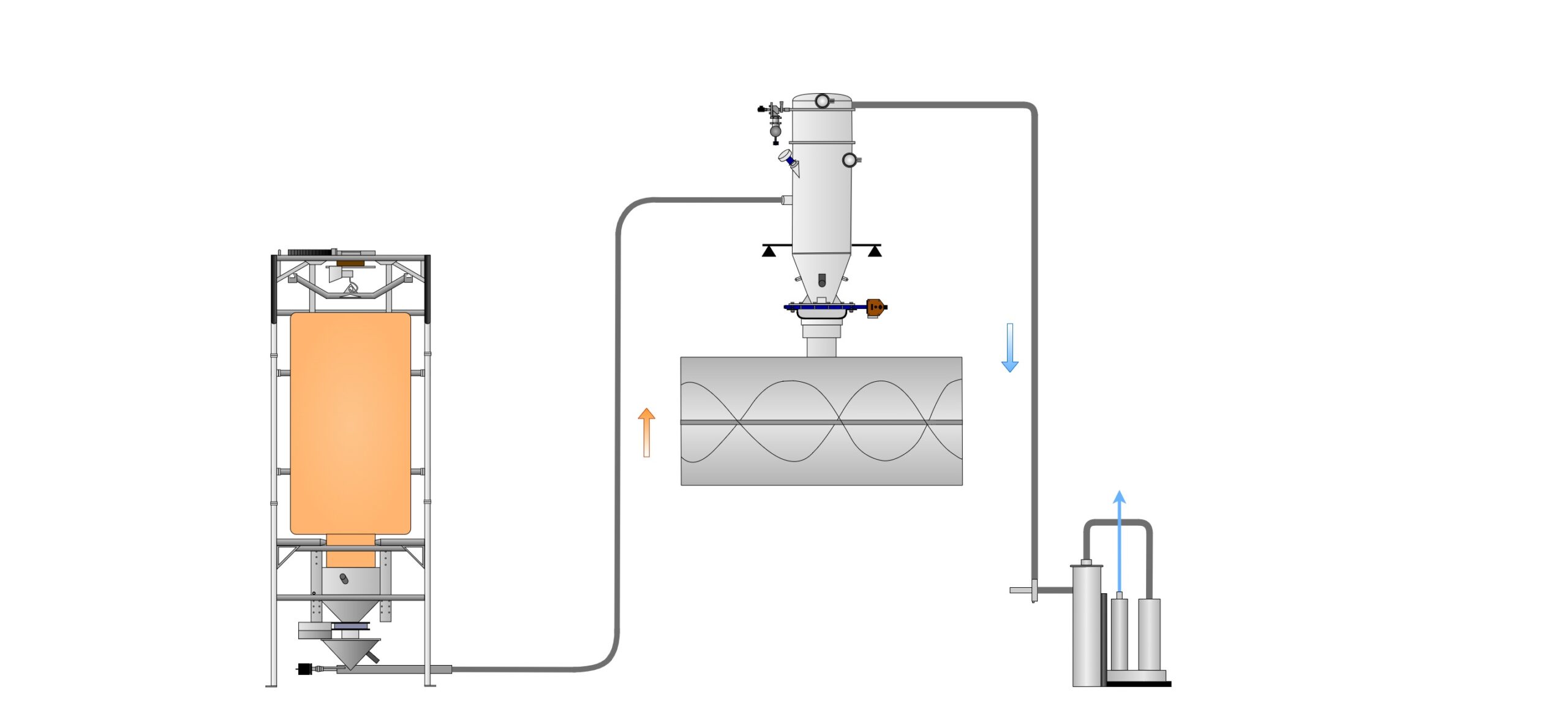

Pneumatic conveying of bulk materials is a dust-free process of transferring dry materials such as powders or granules using suction. Most pneumatic conveying systems transfer products to a vacuum receiver based on a specific time, volume, or weight. At the end of the time sequence or after the appropriate amount of bulk material has been obtained, the discharge valve opens and the conveyed material can be discharged from the receiver.

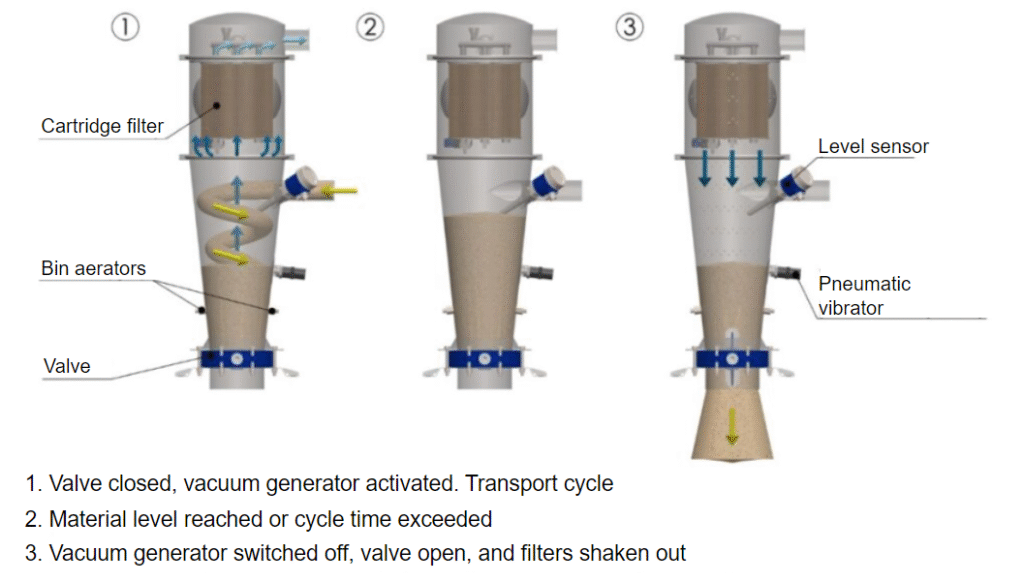

When connected to a vacuum generator and a material intake point, the pneumatic receiver forms a pneumatic transport system. The bulk material is transported through a network of pipes from the material intake point (e.g., pneumatic transport hopper, suction lance) to the pneumatic receiver. The pneumatic receiver is equipped with a level sensor that indicates when it is full. In addition, the receiver can be optionally equipped with a vibrator and/or bin aerators, which facilitate material discharge. Depending on the capacity of the system, the size of the receiver also determines the amount of material sucked in during one cycle. Inside the receiver there is a filter system with an automatic cleaning function. Air from the pressure tank is released through a solenoid valve in the form of a pulse, which cleans the filters. The material release valve is usually a butterfly valve located under the receiver. It is also possible to use a rotary valve to ensure a continuous flow of material. The receiver can also be used as a dosing device, in which case it is placed on a scale, which controls the vacuum transport cycle.

In typical solutions, we offer three sizes of receivers: S, M, and L, which can be equipped with a level sensor and components supporting material discharge (vibrators, bin aerators). In non-standard applications, we manufacture receivers with non-standard capacities.

These elements have a modular design and are ready for quick disassembly. Thanks to the use of special seals and convenient clamps, keeping them clean is extremely easy. It takes only a few minutes to disassemble complete units into their basic components and access the interior.

The vacuum generator is designed to generate negative pressure in a vacuum transport system. It is additionally equipped with a cartridge filter, a dust collection container, and an air flow switch valve.

Pneumatic transport of bulk materials

Advantages:

We offer various components that can work perfectly with your existing or newly built production process

Conveyor line

In its simplest form, it connects the loading point to the receiver. In more complex systems, it includes multi-way valves (diversions), conveyor line relief valves, magnetic separators, etc.

Examples of conveyor line layouts

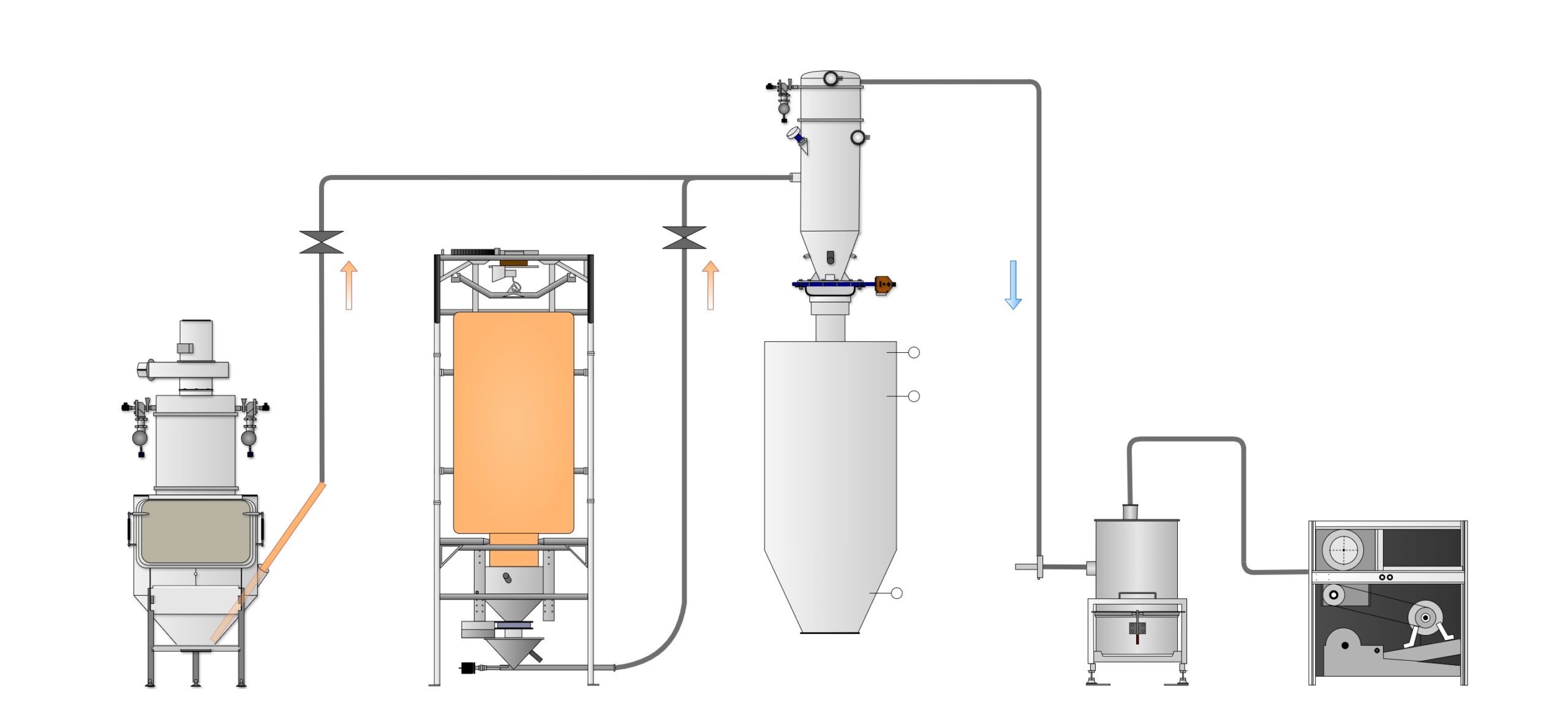

Two loading points

The system decides where the material is to be taken from, either from the STB bag emptying station or from the BSB Big-Bag unloading station.

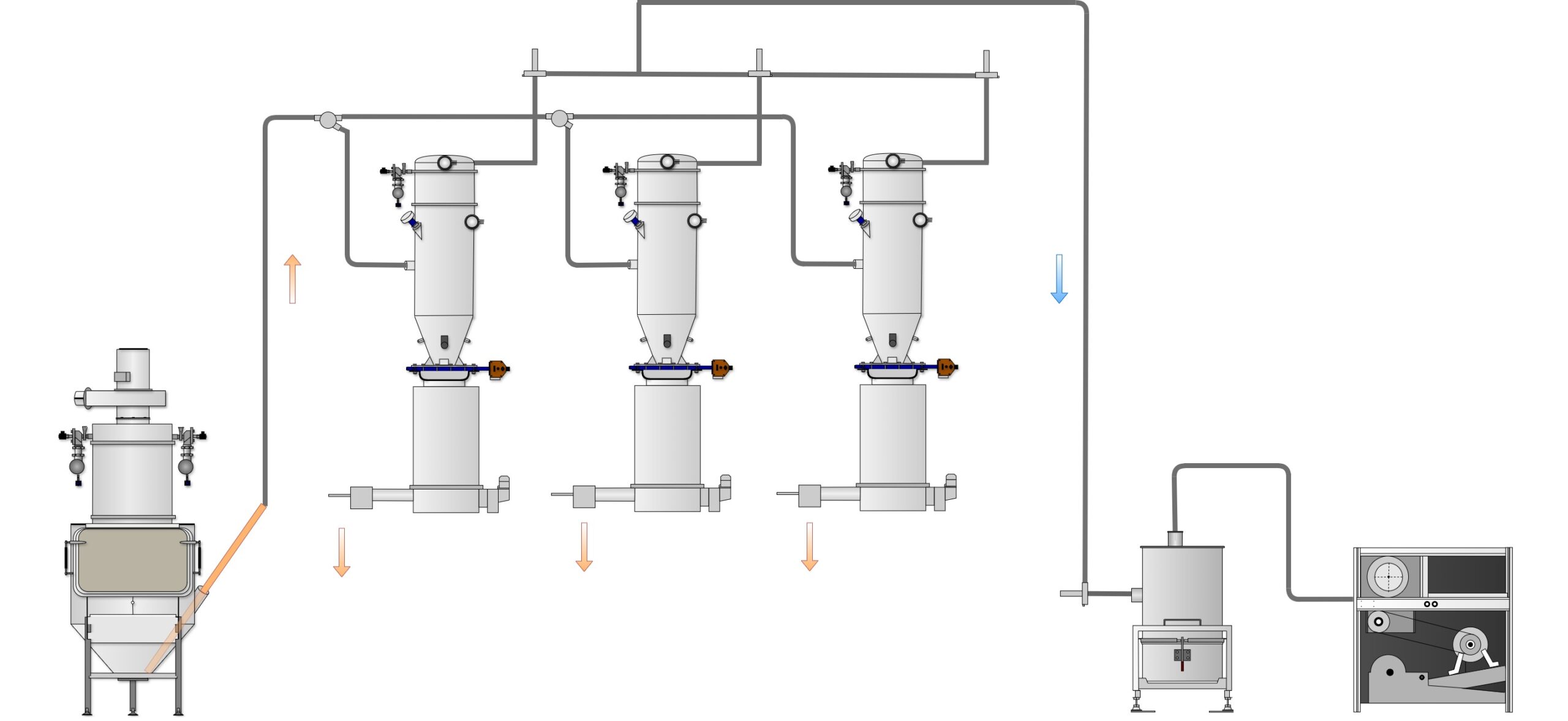

Three unloading points

The transported bulk material feeds three DSL loss-in-weight dispensers. The loading point is the STB bag emptying station.

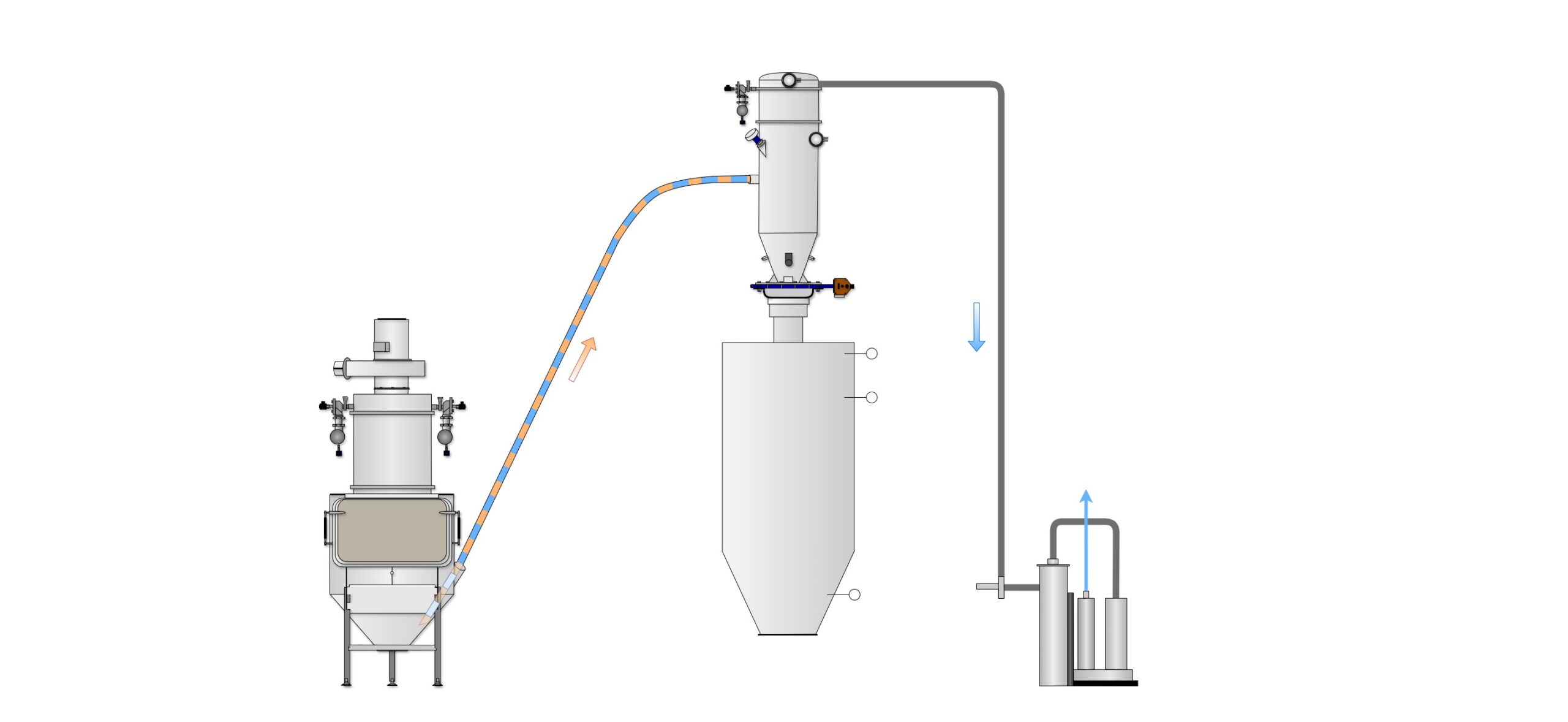

Dense phase

For fragile and delicate materials, the use of the so-called dense phase, i.e., transporting the material at a lower air velocity, is the best solution.

Dosing to the mixer

Vacuum transport systems can also dispense in batch mode, for example when loading a mixer. The accuracy of this solution is <1% of the weight range.

Do ściągnięcia:

Do you need pneumatic transport?

Contact us and our engineers will prepare an optimal solution tailored to your process. We also offer audits of existing installations and modernisation of older transport systems.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7