- InterProcess Sp. z o.o.

BIG-BAG emptying

BIG-BAG unloading stations are devices that enable efficient emptying of large bags with minimal staff involvement.

We configure the stations according to customer requirements, product properties, and environmental conditions.

We build devices that ensure dust-free operation and enable accurate product dosing.

Any conveyor can be installed under the docking station for further transport of the material.

We manufacture stations from powder-coated carbon steel or stainless steel, and components that come into contact with the material are always made of stainless steel.

On special request, we manufacture stations in accordance with food (FDA compliant) and pharmaceutical standards, as well as stations adapted for use in potentially explosive atmospheres (ATEX).

Offer

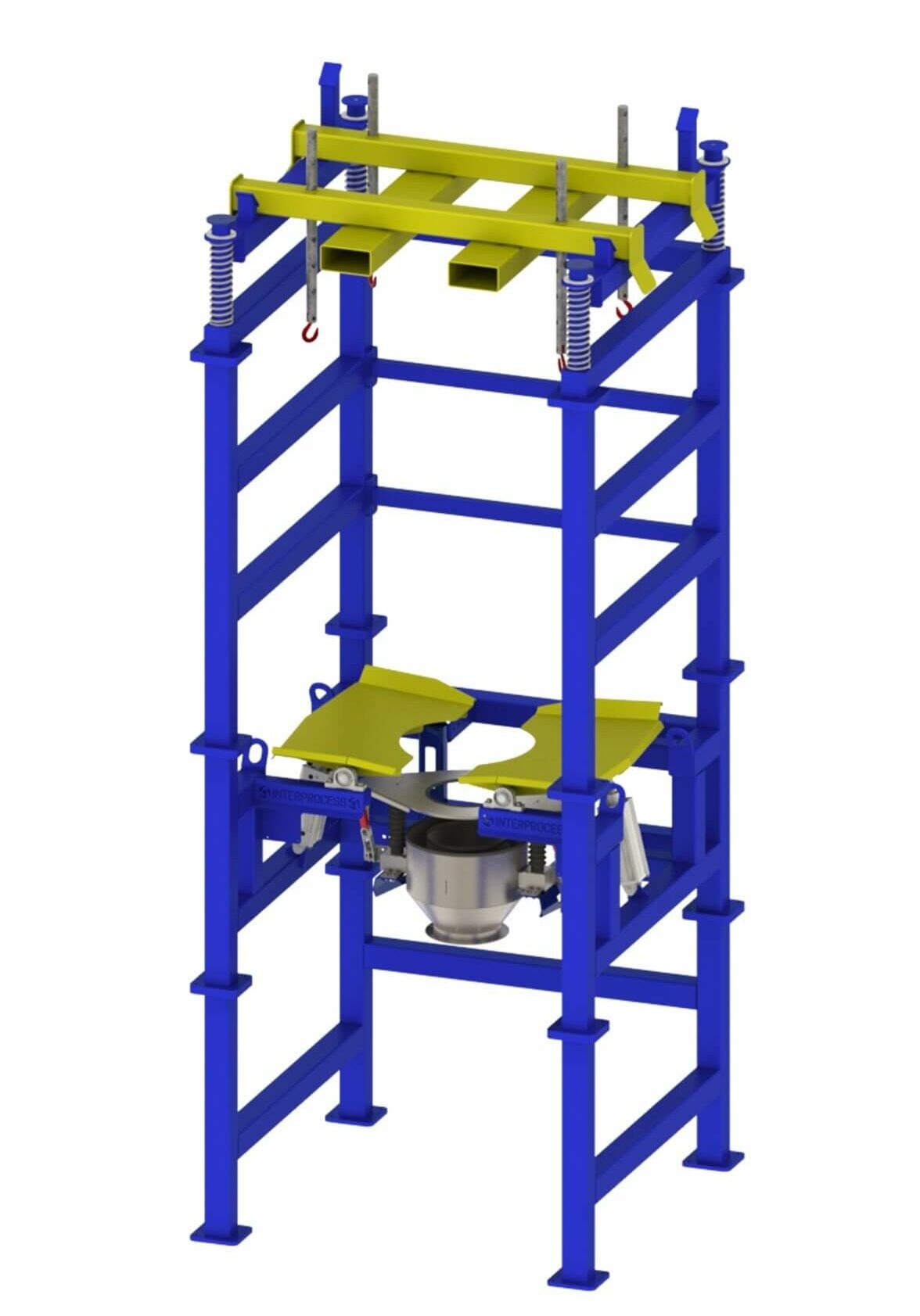

BSB – system rozładunku worków BIG-BAG

The BSB BIG-BAG unloading station is used to empty large bags in a controlled manner. The device ensures a safe, efficient, and dust-free process with minimal employee involvement. The entire structure is made of powder-coated carbon steel or, optionally, 1.4301 (AISI304) or 1.4404 (AISI316L) stainless steel. The bag filled with the product is transported to the docking station by means of an electric chain hoist mounted on a crane, which can be an integral part of the station, or by a forklift truck. The design allows connection to a screw, vibrating or belt feeder mounted under the docking station. The tight connection between the bag and the station ensures that the emptying process is dust-free, and the massaging plates facilitate free flow in the case of materials that are difficult to flow. The station can be connected to a dust extraction system. The components that come into contact with the material are made of stainless steel.

Each unloading station is designed individually, at the customer’s request and according to their needs, for different sizes and types of bags – regardless of whether it is an entire dosing unit with a station, the station itself, or only part of it.

Application:

- Various types of loose materials, e.g., fine-grained and coarse-grained powders, grains, granules.

Specification:

- Structure height depending on application requirements,

- Structure width x length: 1500 x 1500 mm,

- maximum bag height: 2000 mm,

- maximum load capacity: 2000 kg,

- dust-free bag emptying,

- massaging plates to assist material flow,

- frame made of powder-coated carbon steel, optionally made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L),

- can be adapted for use in potentially explosive atmospheres (ATEX).

Download:

Do you need a BIG-BAG station?

Contact us and our engineers will prepare an optimal solution tailored to your process. We offer the possibility of analyzing and adapting the station to a mechanical or pneumatic transport system.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7