- Ku Wiśle 7, 00-707 Warsaw

- +48 787 783 590

- biuro@interprocess.pl

BIG-BAG filling

BIG-BAG filling stations are devices that enable efficient filling of large bags with minimal involvement of staff. We configure the stations according to customer requirements, product properties and environmental conditions. When filling BIG-BAGs, screw feeders, vibrating feeedrs or belt weighfeeders can be used. We build devices ensuring dust-free operation and enabling accurate dosing of the product. The modular system allows you to adapt the station to the type of bag. We make carbon steel, powder painted stations and the elements in contact with the material are made of stainless steel. On special request, we make stations in food (in accordance with FDA requirements) and pharmaceutical standards or adapt the station to work in an explosion zone (ATEX).

Offer

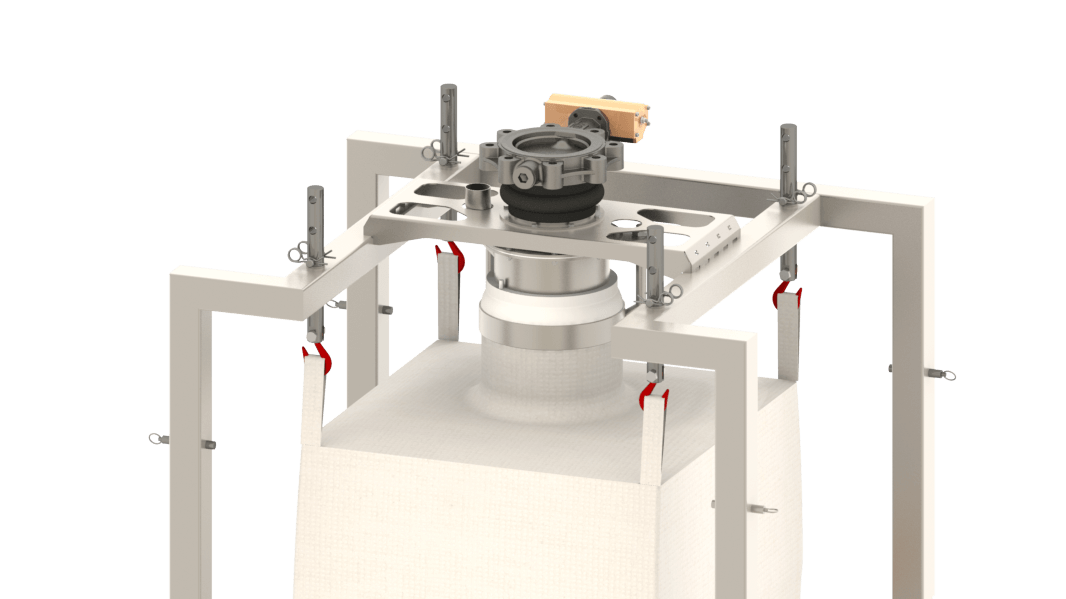

BSA – BIG-BAG filling system

Our BIG-BAG filling station enables a simple and efficient process of filling large-size bags, with minimal staff involvement. The empty bag is attached to four handles in the upper corners of the frame. Then the inlet of the bag is pulled on the filling downpipe of the station. The tight connection between the bag and the tube guarantees dust-free operation. The material can be fed into the bag using any feeder. The BIG-BAG filling station can be equipped with a weighing platform, used to control the amount of material in the filled bag, and an automation system that stops the raw material flow after filling the bag to the required weight. After filling the flexible bag and removing it from the steel frame, it is lifted by a forklift and transported to another place. The structure is made of carbon steel, powder painted. Optionally, it can be made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L), so that the station can be used in the food industry. The modular design allows the station to be adapted to the type of bag.

Each filling station is designed individually, on request and according to customer needs, for different sizes and types of bags.

Applications:

- various loose materials, e.g. fine- and coarse-grained powders, granules

Specification:

- construction height from 2000 to 3000 mm,

- width x length of the construction: 1210 x 1445 mm,

- maximum bag width: 1000 mm,

- maximum bag height: 2000 mm,

- maximum load capacity: 2000 kg,

- dust-free filling of the bag,

- frame made of carbon steel, powder painted,

- optionally made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L),

- can be made for explosion zone (ATEX).

Download: