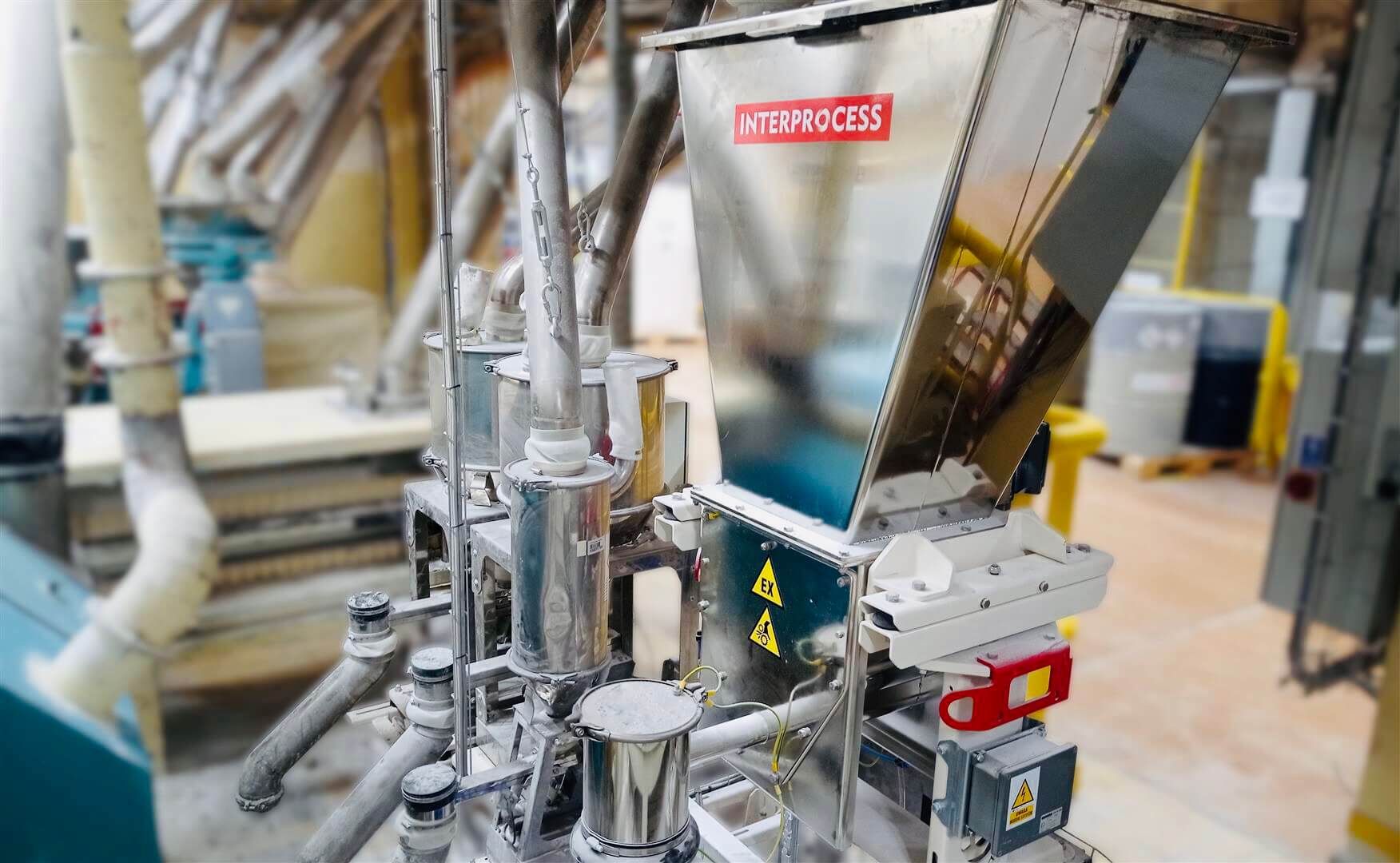

- InterProcess Sp. z o.o.

At InterProcess, we design and supply complete technological lines for handling and processing bulk materials – from raw material reception, through transport, storage, dosing, and mixing, to automatic process control.

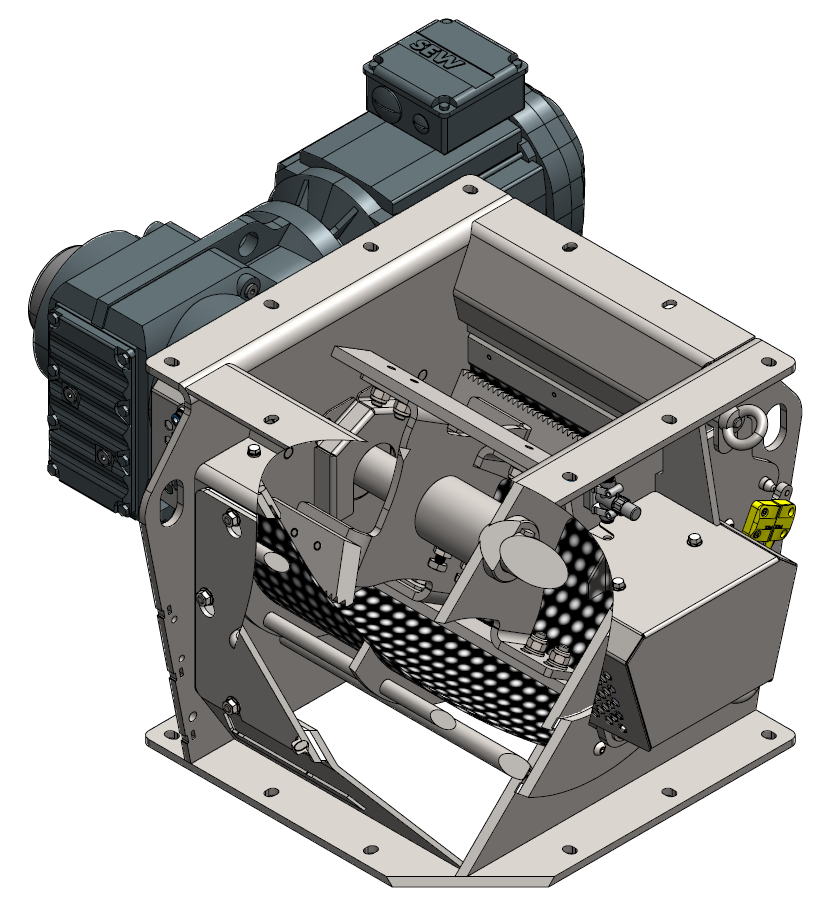

We combine engineering experience with our own production of equipment and control systems to create efficient, precise, and reliable process installations tailored to the individual needs of our customers.

Our solutions can include both individual devices and complete process lines.

Some of our customers are looking for machines or modules, such as Big-Bag stations, transport systems, or dosing units, to modernize or increase the efficiency of their existing production line.

Others opt for a comprehensive turnkey solution.

In each case, we ensure full integration and compatibility of our equipment with the existing infrastructure.

Our Offer Includes, Among Others:

- Big-Bag loading and unloading stations,

- pneumatic and mechanical transport systems,

- screw, vibratory, and belt feeders, and mass flow meters,

- raw material mixing and conditioning systems,,

- storage silos and material collection systems,

- HMI operator panels and SCADA visualization systems,

- process control automation and integration with master systems.

Thanks to our modular design and flexible approach, we tailor our solutions to the requirements of every industry – food, chemical, pharmaceutical, feed, construction, and many others.

Why Choose InterProcess?

- many years of experience in bulk material process engineering,

- in-house production of equipment and control systems,

- the ability to implement individual modules or complete turnkey lines,

- full technical, design, and service support,

- solutions tailored to the needs and scale of production.

Whether you need a single device, an upgrade to your existing installation, or a new production line, we provide comprehensive support – from concept, through design and implementation, to commissioning.

We create systems that guarantee reliability, efficiency, and safety in your production process.

Do you need technical support?

Contact us and our engineers will prepare an optimal solution tailored to your process. We offer the possibility of testing selected devices with your bulk material.