- InterProcess Sp. z o.o.

Stations supporting manual bag emptying

Our goal is to simplify and streamline all processes related to the handling of bulk materials so that they are simple and trouble-free. During the seemingly simple task of emptying small bags, dusting is a common problem. Our STB stations are a convenient solution to this problem.

The device ensures a simple and dust-free process of emptying small bags. The station is designed for use with as many devices for further transport of bulk materials as possible. Depending on customer requirements, the structure can be made of powder-coated carbon steel or AISI304 or AISI316L stainless steel (glazed or electropolished). Thanks to the ergonomically designed worktop, the bag emptying process is extremely convenient, which avoids the risk of spinal injuries, and the feed grid protects against unwanted foreign objects entering the device.

Advantages

- dust-free emptying of small bags,

- automatic filter cleaning using a built-in controller and 6 bar compressed air,

- ergonomic design minimizing the risk of back injuries,

- modular design, thanks to which the station can be equipped with a number of functions such as a bag compactor, rare earth magnet, rotary valve, bottom suction unit, or screw feeder,

- very simple operation,

- feed chute preventing unwanted foreign objects from entering the device,

- work surface ensuring convenient bag emptying,

- suitable for a wide range of bulk materials.

STB bag unloading stations are a great solution when small amounts of material need to be fed into the process.

The device is designed for bulk products delivered in bags with a capacity of up to 50 liters. They provide a convenient way to empty and feed small amounts of product into the main process, e.g., into a mixer or a transport system between two distant points of the process installation. They are a safe solution that helps to avoid back injuries and minimize dusting.

Thanks to its modular design, it can be equipped with a range of additional devices such as a bag compactor, rare earth magnet, rotary valve, bottom suction unit, or screw feeder.

A built-in exhaust fan with a filter system and automatic cleaning function helps to keep the equipment clean.

Offer

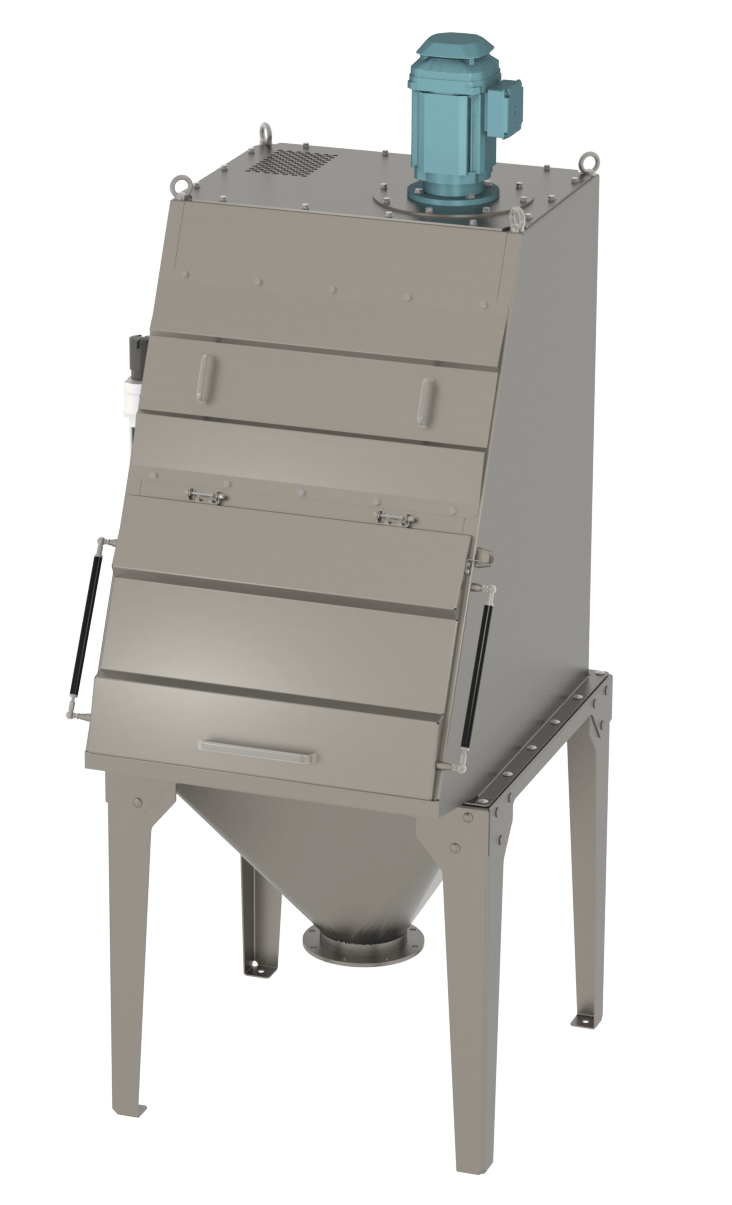

STB-V1 – manual bag emptying station

Specification:

- SEW 1.1 kW 3×400/3×500 VAC exhaust fan,

- cartridge filters with an area of 8-12m2,

- automatic filter cleaning using a built-in controller and 6 bar compressed air,

- convenient worktop for easy bag placement and a feed grid (for safe unloading),

- access flap equipped with gas springs and a position sensor that activates the exhaust fan or sequential filter cleaning.

Construction:

- 304 stainless steel (glass-bead blasted or electropolished),

- 316L acid-resistant steel (glass-bead blasted or electropolished).

Intended use:

- various types of dusty bulk materials, e.g., fine-grained and coarse-grained powders, grains, granules

Download:

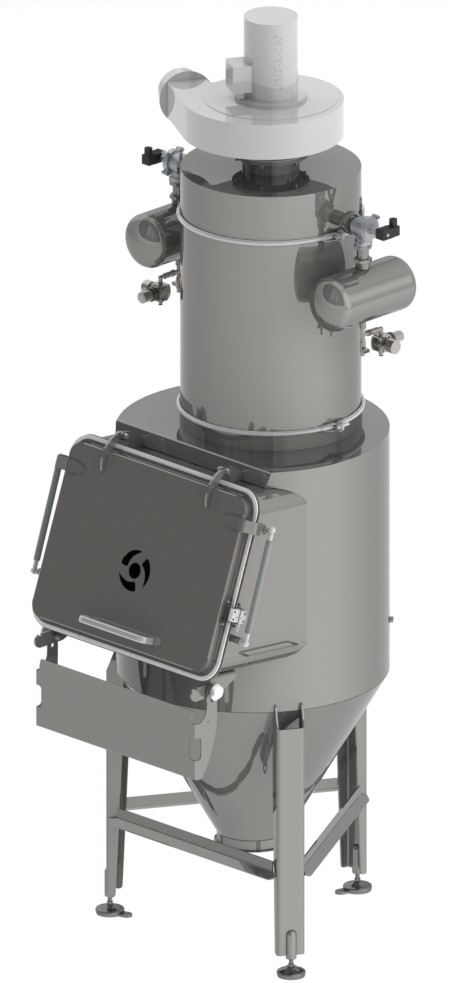

STB-V2 – manual emptying station for small bags

Specification:

- 0.75 kW exhaust fan 3×400 VAC,

- cartridge filters with an area of 8m2,

- automatic filter cleaning using a built-in controller and 6 bar compressed air,

- convenient tabletop for easy bag placement and feed grid (for safe unloading),

- access flap equipped with gas springs and a position sensor that activates the exhaust fan or sequential filter cleaning.

Construction:

- 304 stainless steel (glass bead blasted or electropolished),

- 316L acid-resistant steel (glass bead blasted or electropolished).

Intended use:

- various types of dusty bulk materials, e.g., fine-grained and coarse-grained powders, grains, granules

Download:

Options

- Station with built-in fan

- Station without built-in fan, using an external dust extraction system

- Empty bag compactor

- Rare earth magnet

- ATEX version for zones 21 and 22.

- Unloading aids:

- vibrating aeration pad

- vibrator

The lower part of the station can be designed to work with:

- a screw feeder

- a rotary valve

- a bottom suction unit

- a butterfly valve or knife gate valve

- a suction lance

- a vibrating screen

How to use the station

Step 1: The operator opens the access flap, which activates the exhaust fan.

Step 2: The operator places the bag on the station counter inside the station, then cuts it open and empties the contents directly into the station tank (or the device below). The air flow generated by the exhaust fan causes the dust rising from the emptied material to be drawn into the station.

Step 3: The dusty air is filtered through cartridge filters located inside the station. After unloading, the operator closes the access flap. The dust deposited on the surface of the filters is blown off by sequentially operating compressed air nozzles. Automatic filter cleaning only takes place when the cover is closed and the fan is not running, so as not to create additional dust during unloading.

Do you need a station for emptying bags?

Contact us and our engineers will prepare the optimal solution tailored to your process. We offer the possibility of analyzing and adapting the station to a mechanical or pneumatic transport system.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7