- InterProcess Sp. z o.o.

Preparation of Mixtures

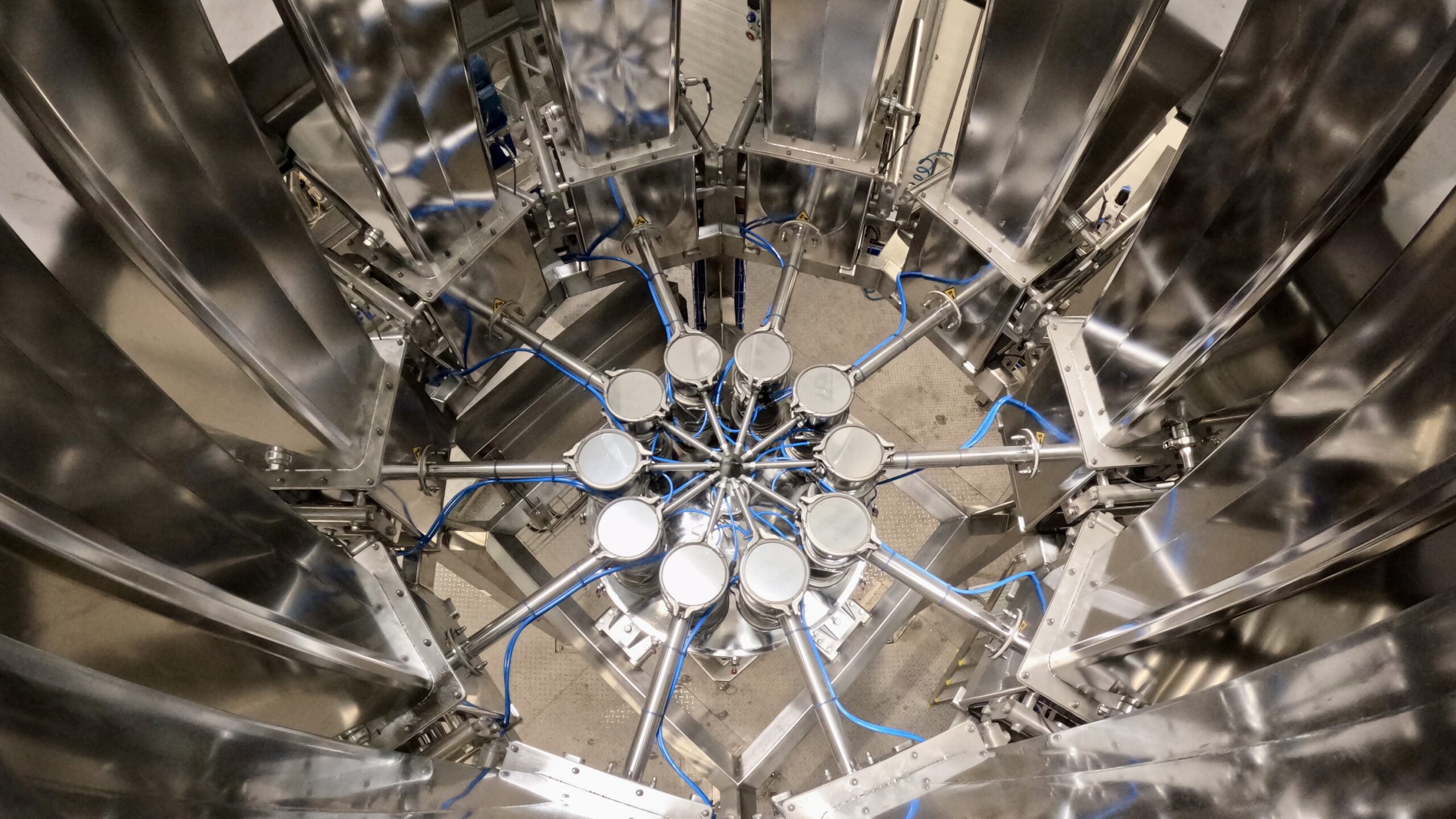

The versatility of our screw feeders makes them ideal for installation in a multi-component dosing station, where each feeder supplies a separate material. A central control system determines the portion size or required flow rate based on the data contained in the recipe. This type of application can be used for both batching and continuous feeders, depending on the type of production line in the plant. Our solutions provide for dosing to an external scale (gain-in-weight) or directly from the scale (loss-in-weight), which is then equipped with each of the dispensers. In the latter case, the process can be carried out in parallel and undergoes preliminary homogenization already at the dosing stage.

Solution Variants – Batch and Continuous Dosing

In fact, the solution used depends on the type of process, the number of ingredients, the operating regime, the dosing time, and the required accuracy.

In batch dosing systems, the most common and cost-effective solution is a system with a centrally located scale. Similar variants, where extremely high accuracy is required, include the use of intermediate scales, e.g., with a rotating bowl. Another solution may be to install a mobile scale on a rail, which automatically positions itself under each subsequent dosing unit and is filled according to a predefined recipe. After dosing, the mixture should be transferred to a mixer, where it is fully homogenized.

In continuous dosing systems, the devices operate in parallel and the material is fed not on the basis of the batch size, but on the basis of flow control of all components according to the appropriate proportions. It is easy to imagine that this type of mixture is already quite well mixed at the moment of combination. Additional flow mixers are sometimes used to increase the degree of homogenization, but they are not as large and do not consume as much energy as batch mixers. The continuous dosing and mixing process itself often proves to be cheaper and easier to use in the long term (despite the higher initial investment cost).

Hygienic and Easy To Clean

As a company specializing in the most demanding industrial sectors, we pay particular attention to ensuring that cleaning does not cause too many problems for employees and that the safety of the bulk product is of the highest standard. Additional features such as easy-to-open panels, flaps, and covers allow for quick opening of the equipment and access to the interior. Removable and detachable pipe connection elements and special compensators ensure that inspection of the process installation is easy. The special hygienic design, which includes dedicated components, minimization of dust-collecting surfaces, and grinding and polishing of surfaces in contact with the material, also improves the quality of your product and facilitates equipment maintenance.

How Can We Help You?

Using our experience and your knowledge of the process, we will help you select the right equipment and layout for your bulk material processing line.