- InterProcess Sp. z o.o.

Dust-Free Packaging Filling Lines

When producing mixtures of loose materials and filling packaging with small portions, very high accuracy and filling speed are required. It is important to use a universal system that meets customer requirements in a practical way – it is ideal for dust-free filling of various types of packaging, such as cardboard boxes or barrels, to the required weight – from 10 to 100 kg. At InterProcess, we approach each project individually, taking into account all customer wishes and needs, with attention to the smallest details. The lines for dust-free filling of cardboard boxes and barrels meet strict hygiene requirements and guarantee easy operation. Depending on customer requirements, it is possible to design the device in accordance with the ATEX directive or FDA requirements.

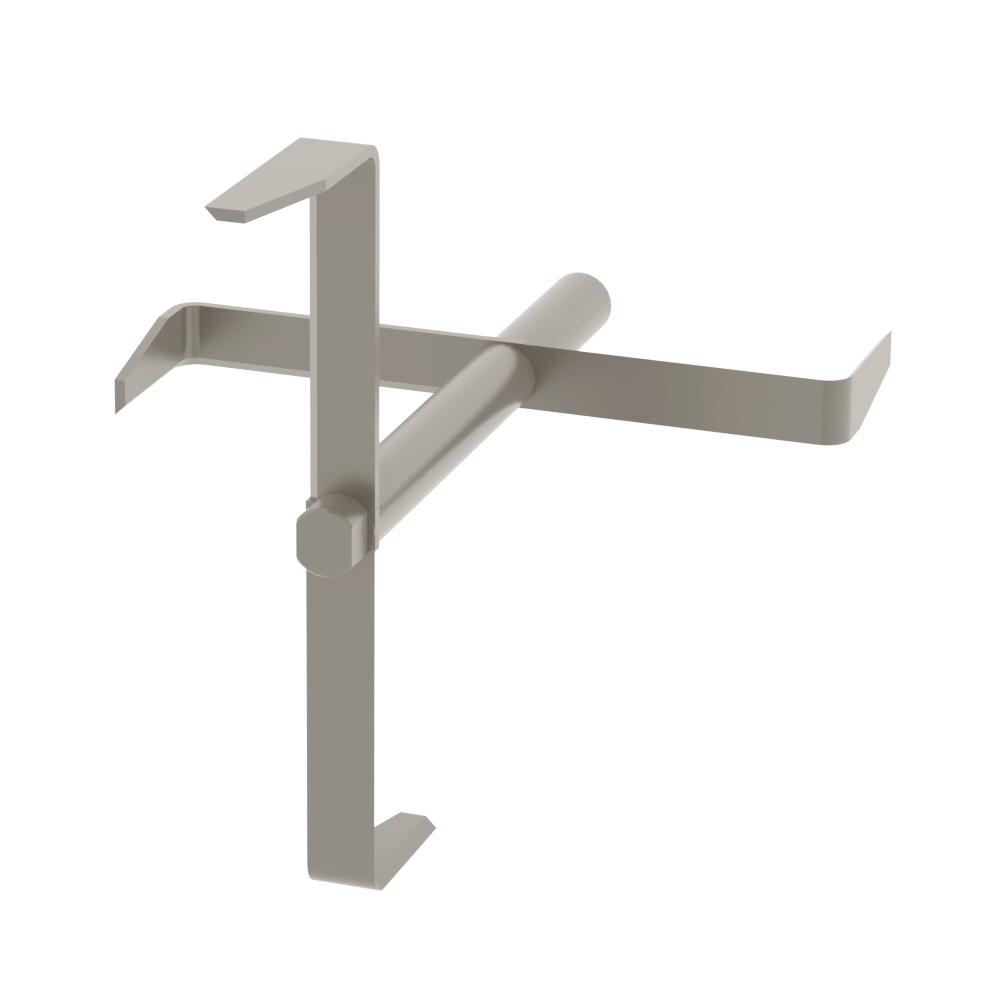

The dust-free filling station can be placed directly under mixers or buffer tanks, or the material can be fed from a BIG-BAG. The main element of the entire line is a volumetric screw feeder, which controls the filling process, together with a hopper with a geometry that facilitates material flow. The hopper is equipped with two fill sensors – minimum and maximum. When the minimum value is reached, the system automatically fills the hopper to the maximum value without interrupting the operation of the device. Thanks to various types of screens, we can be sure that no foreign particles will end up in the final packaging. Depending on the type of container being filled (bags, boxes, barrels), the station can be equipped with various heads with an inflatable seal, which ensure a tight connection and a dust-free filling process. In addition, the line is connected to a dust extraction system. Thanks to its modular design, it is extremely easy to adapt to customer needs. It is a universal solution for different container sizes thanks to a system that allows for quick adjustment of the distance between the rollers and the head. Our lines can be equipped with wheels, allowing them to be moved freely around the plant. In the model presented, we have equipped the device with an additional, certified scale at the customer’s request.

Principle of operation—lines for dust-free filling of containers

In the case of bags or boxes with inserts, the filling process is performed manually. The operator places the bag or film from the box on the head, closes the clamp, and activates the seal pumping process with a foot switch, which ensures a completely tight connection. Then, the dust-free filling process is started using a second foot switch. Dosing takes place automatically until a specified weight is reached, after which the system unseals the connection, allowing the container to be freely disconnected. The system can also be designed to operate fully automatically when filling rigid containers, such as barrels.

Continuous replenishment of material

The raw material is fed into the main chamber of the dosing device from a hopper with a geometry that facilitates material flow, equipped with two level sensors – minimum and maximum. When the minimum value is reached, the controller automatically starts filling the hopper to the maximum level without interrupting the packaging process.

Reliable flow

Screw dispensers are equipped with a horizontal agitator driven by a separate electric motor, operating at a constant speed, which ensures complete filling of the dispensing element and protects against material jamming. For products that are particularly difficult to dispense, it is possible to install an additional vertical agitator.

Precision scales

At InterProcess, we know how to use strain gauge measuring systems in the most optimal way, and our designs are reliable and dependable solutions for weight measurement. We offer platform scales of various sizes, including certified ones, made of carbon and stainless steel, tailored to the needs of our customers.

Weighing automation

We offer special weighing controllers from the Dutch company PENKO with dedicated MFL (Mono Fill) software for our lines, enabling a simple and fully automated process of dust-free filling of various types of containers.

Dust-free filling process

The bag from the container should be placed on the head and the clamp closed – the container is then pre-mounted. When the operator presses the foot switch, the seal is inflated, ensuring a completely tight connection and a dust-free filling process.

Versatility

Thanks to the use of a screw feeder with different types of feeding elements depending on the material being fed, no challenge is too great for us. We can feed virtually any type of dry bulk material – both free-flowing and difficult-to-flow, easily aerated, prone to uncontrolled flow or clumping.

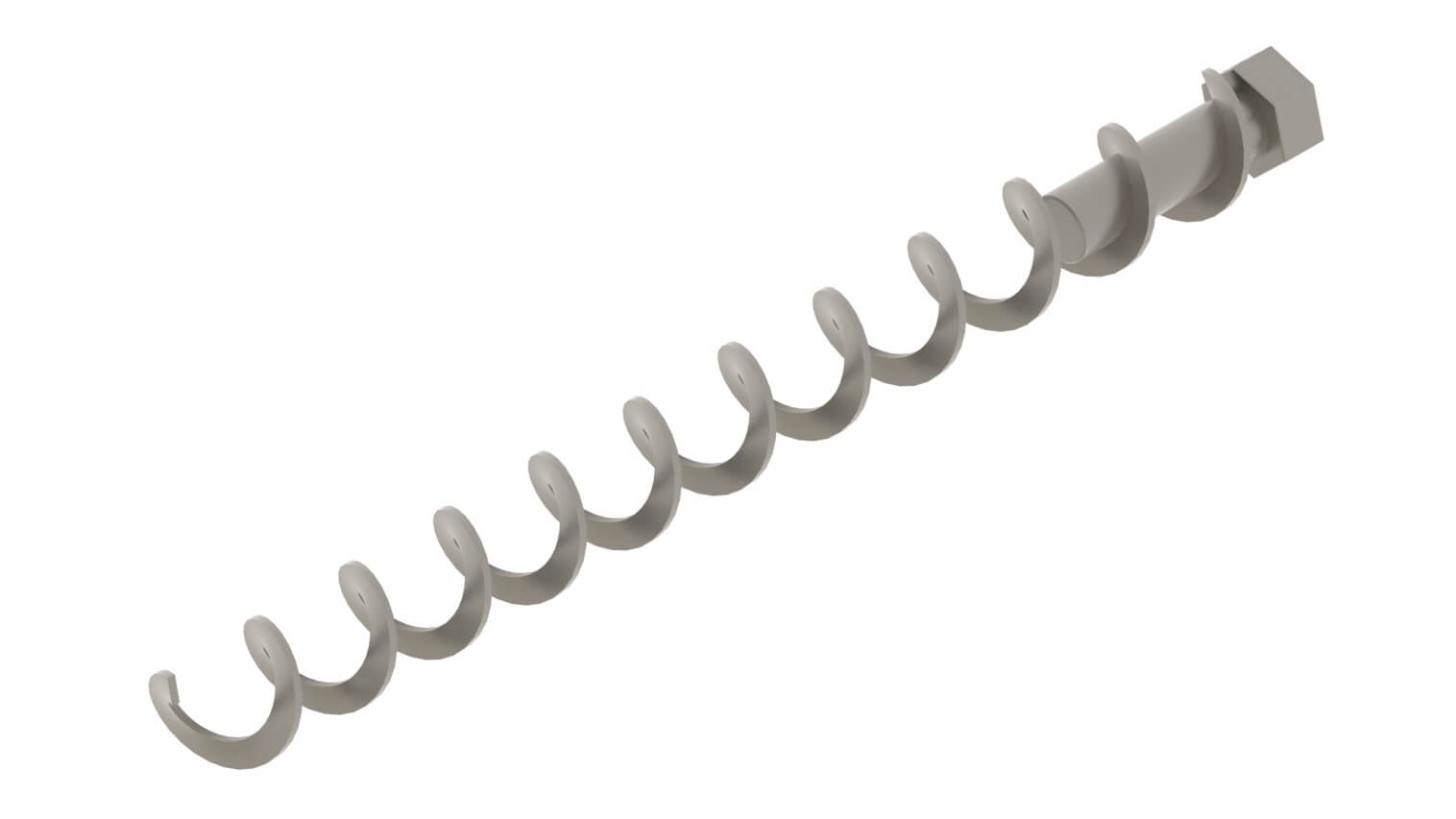

Spiral

Application for materials:

- difficult to flow (e.g., flour, soda, granules)

- fine and sticky, and prone to accumulating on the guide pin (e.g., cocoa, titanium white)

- consisting of large particles that can accumulate, causing high friction between the guide pin and the surface of the flow tube

- requiring much better hygienic conditions (e.g., foodstuffs)

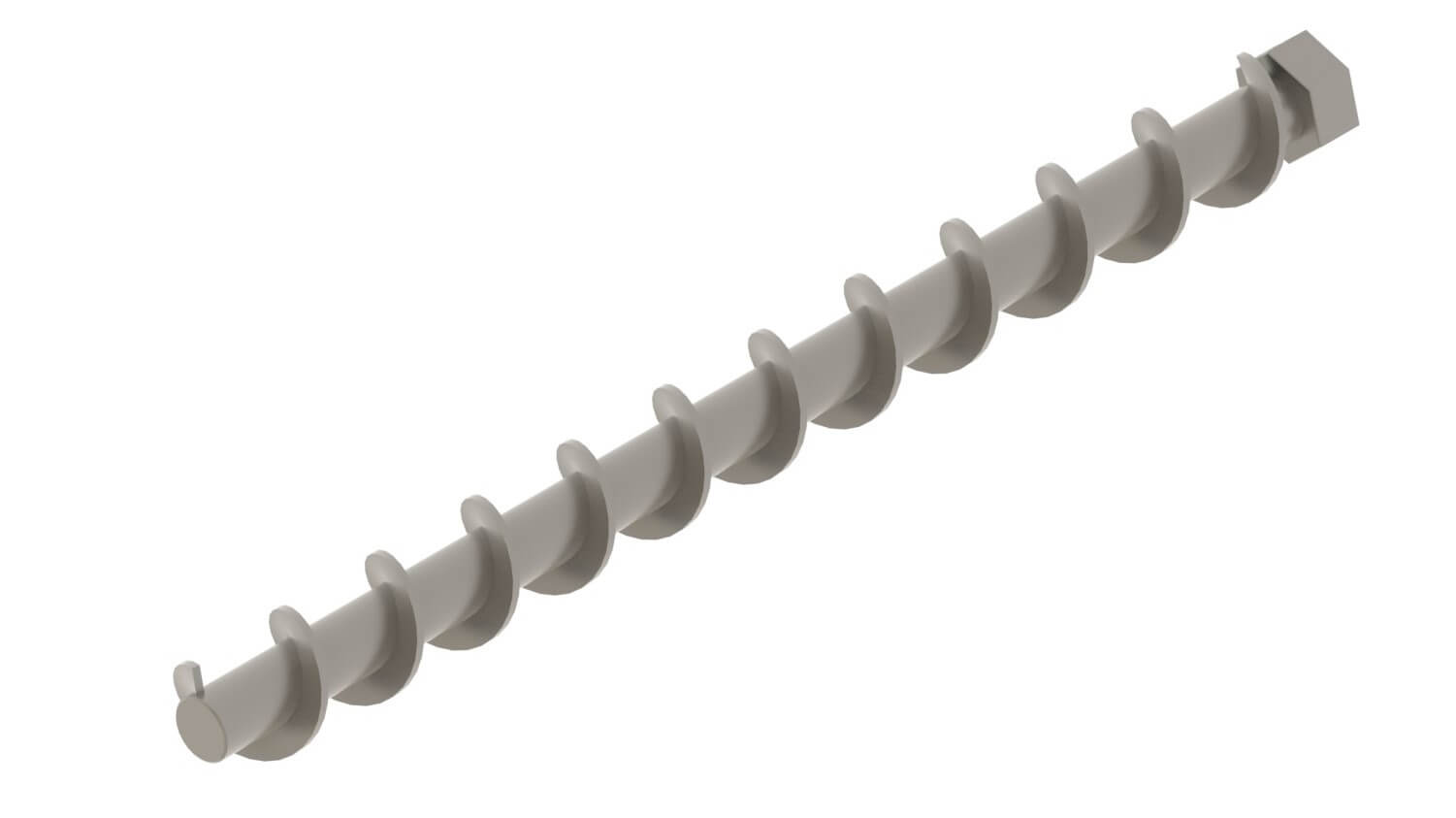

Screw with guide pin

Application for materials:

- free-flowing and very loose (e.g., salt, sugar)

- easily aerated, with a tendency to flow uncontrollably (e.g., carbonates, gypsum)

- highly abrasive (e.g., quartz sand)

- brittle (e.g., flakes, instant coffee)

Advantages – dust-free packaging filling lines

- Dust-free and accurate filling of various types of packaging

- Automated line operation thanks to PENKO SGM800, 1020, FLEX, and 2100 controllers with MFL (Mono Fill) software or custom-developed software

- Screens ensure that no foreign particles end up in the packaging

- Universal solution – can be used for a wide range of products thanks to the use of a screw feeder

- Modular design allows for custom configuration and expansion of the line

- Legalized scales in the range from 10 to 100 kg

- Can be adapted for use in potentially explosive atmospheres (ATEX) or made of materials compliant with FDA requirements

- Individual approach to the project

Do you need a line for filling bags, cardboard boxes, or barrels?

Contact us and our engineers will prepare an optimal solution tailored to your process. We offer the possibility of dosing tests and adapting the line to work with a mechanical or pneumatic transport system.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7