- InterProcess Sp. z o.o.

Big-Bag Systems

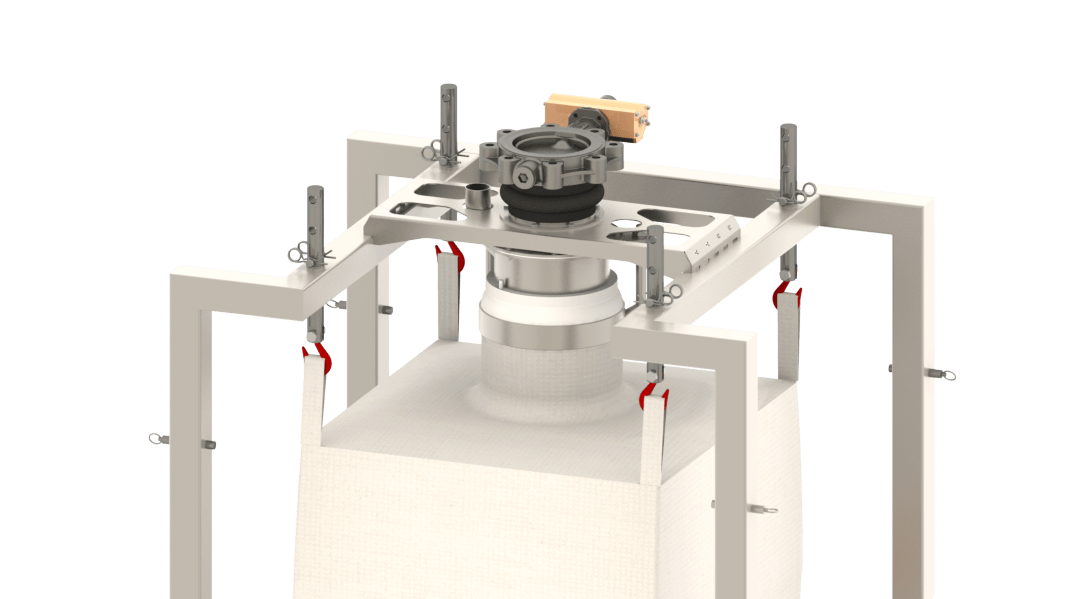

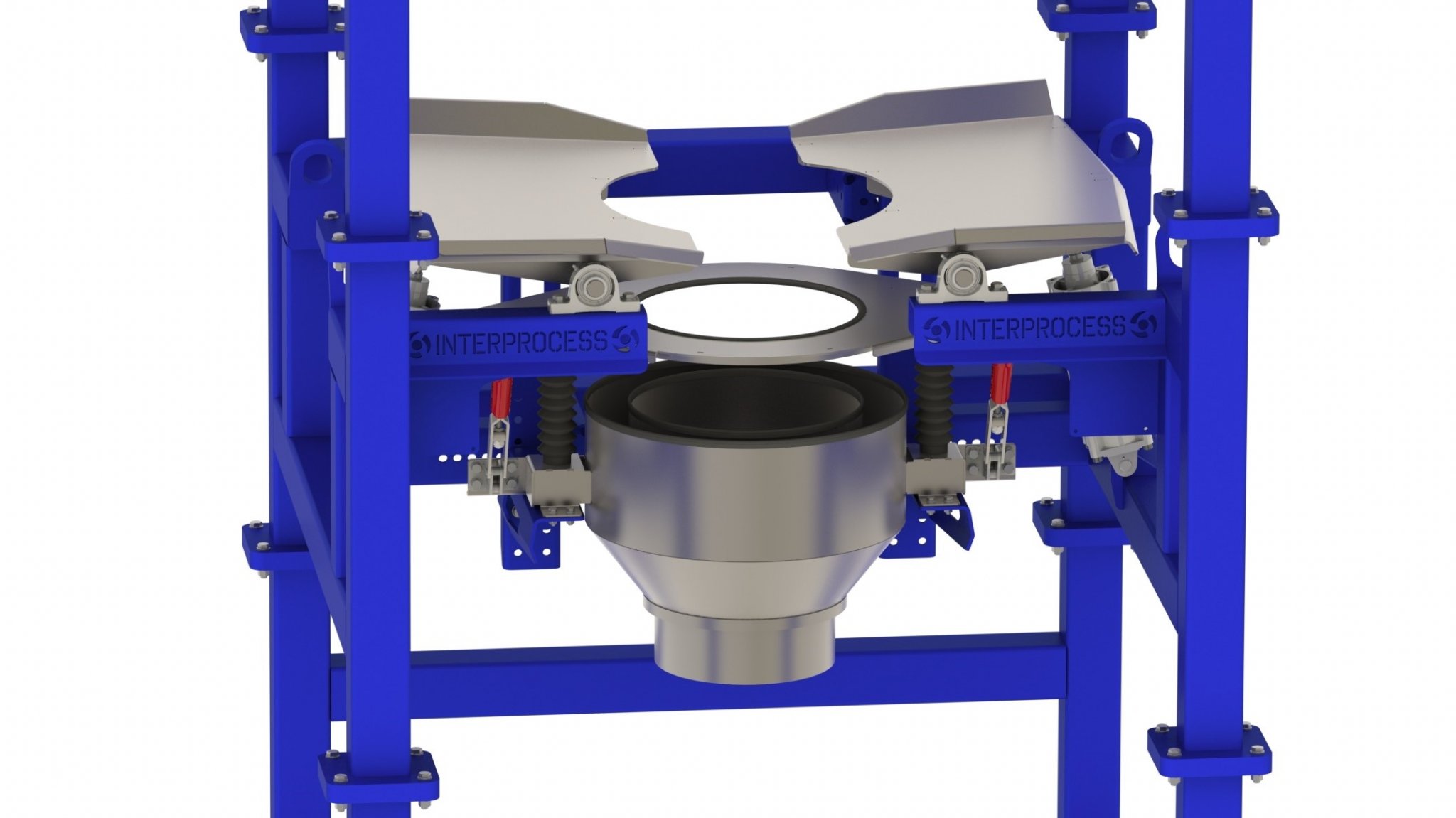

Big-Bag systems are becoming increasingly popular in industry. They are a great solution when bulk material needs to be stored and transported safely and inexpensively. However, dusting and spillage are common problems when using them. At InterProcess, we offer stations for loading and unloading large bags, which are a great solution to this problem.

Regardless of whether the product is in powder or granule form, flows easily or with difficulty, or whether the process takes place in an explosion hazard zone, our BIG-BAG loading stations and entire Big-Bag systems meet the highest safety and hygiene standards for the product and operating personnel.

The stations for emptying large bags manufactured by us make this process extremely simple and fast. It requires reliable and proven user-friendly solutions, which we develop based on our many years of experience. InterProcess BIG-BAG unloading stations are designed from scratch at the customer’s request, with attention to the smallest details.

Customized Big-Bag systems

We create customized solutions for loading and unloading Big-Bags. We provide assistance and technical support at every stage of the project – from project definition, through planning and production, to commissioning. Thanks to our solutions, the design can be perfectly tailored to the customer’s needs – regardless of whether you need an entire station with a dosing system, the station itself, or only part of it. Limited space or working in difficult conditions is not a problem for our equipment.

Continuous and dust-free operation

A secure and dust-tight connection between bags and the docking station during filling and emptying of large bags is our top priority. We offer appropriate connection and safety systems. Our material massaging systems guarantee continuous operation, and downtime caused by bag changes is very short thanks to the easy and intuitive operation of the station. As experts in our field, we meet the requirements for products that are difficult to flow or require gentle handling. All these processes must be carried out with high precision and speed. To achieve this, we offer the appropriate weighing and control technology. The frame is made of powder-coated carbon steel. Optionally, it can be made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L). The parts that come into contact with the material are made of stainless steel.

Advantages of Big-Bag systems

Designed for specific technological processes, these structures ensure, among other things:

- dust-free filling and emptying of bags, with minimal staff involvement,

- short downtimes, thanks to the ease of connecting bags,

- reduced risk of damage to bags, which can be reused multiple times, thus saving money,

- reduced losses due to spillage of goods,

- quick and very easy loading and unloading of goods from bags,

- increased work safety during loading and unloading tasks.

Do you need a station for Big-Bags?

Contact us and our engineers will prepare the optimal solution tailored to your process. We offer the possibility of analyzing and adapting the station to a mechanical or pneumatic transport system.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7