- InterProcess Sp. z o.o.

Pressure transport, also known as pneumatic transport with overpressure, is a modern method of transporting bulk materials such as powders, granules, and grains using compressed air. Thanks to its versatility and efficiency, it is used in many industries.

Key advantages:

- Long-distance transport (even >100 m)

- Minimization of losses and dust emissions

- Closed system – high level of hygiene and safety

- Easy installation – pipelines can be routed vertically and horizontally

- Process automation – integration with dosing, weighing, and control systems

What is pressure transport?

In a pressure transport system, material is forced into a pipeline using compressed air. The air stream “pushes” the material through the pipeline to the receiving point, where it is separated and unloaded.

Types of pressure transport

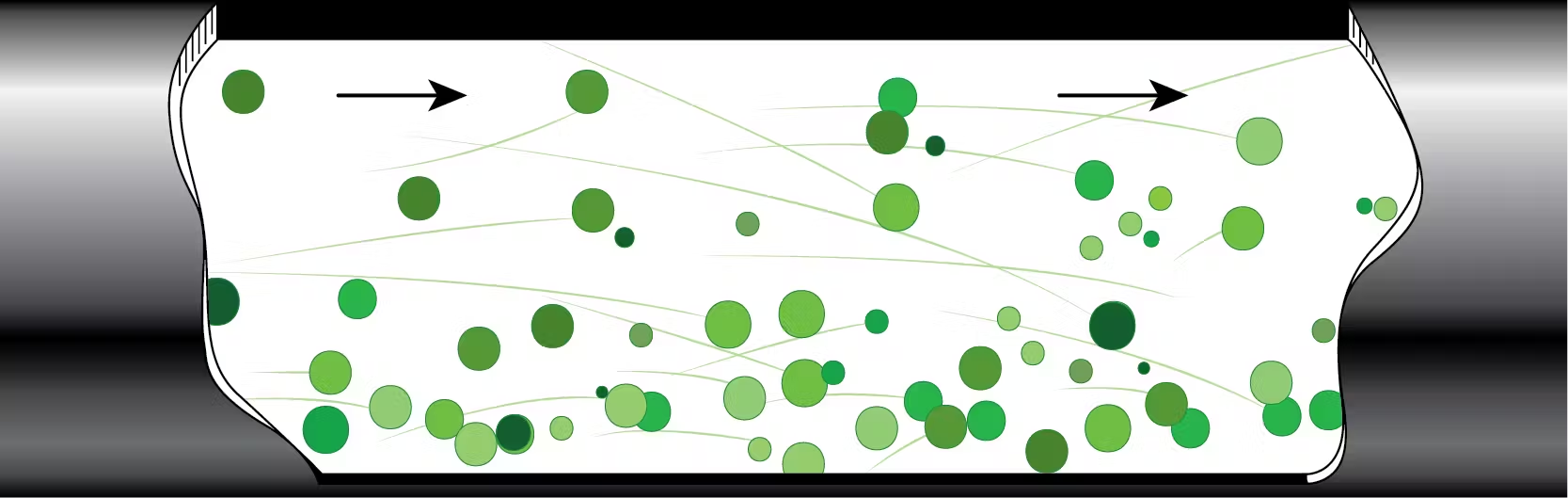

Lean phase transport

- The material is carried in a high-speed air stream.

- Ideal for light and dry materials.

- Longer distances and greater transport heights.

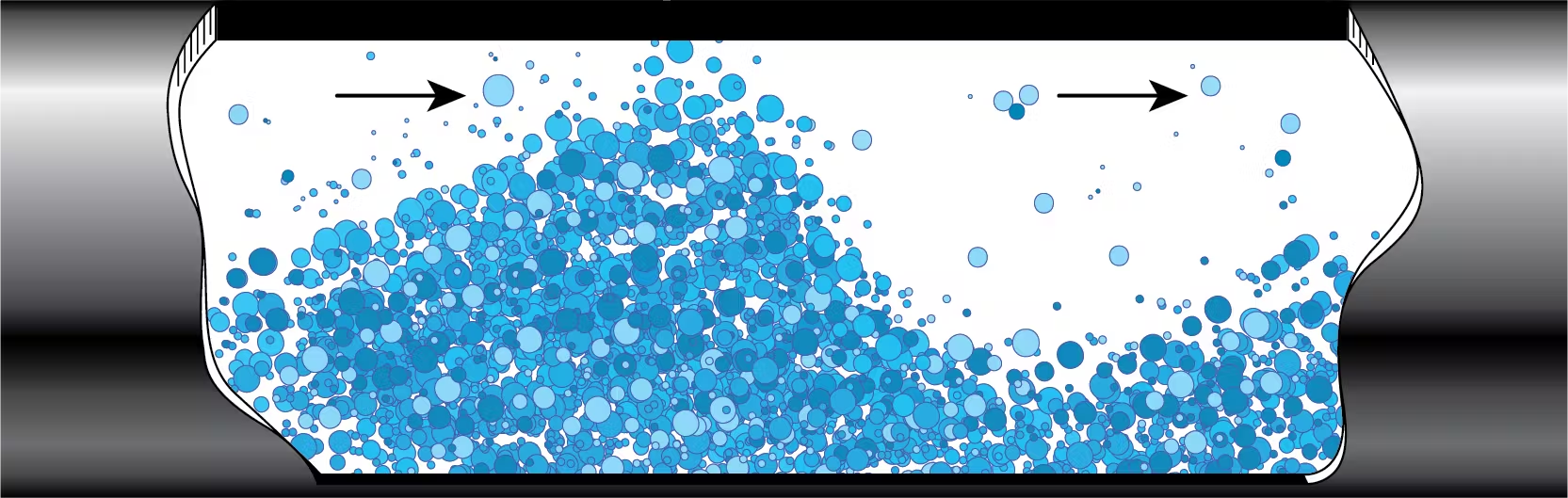

Dense phase transport

- The material is transported in batches, with less air.

- Suitable for delicate, abrasive, or heavy raw materials.

- Reduced energy consumption and lower risk of particle damage.

Design assumptions

What can be transported?

- Food industry: e.g., flour, sugar, cocoa, starch,

- Pharmaceutical industry: e.g., various types of powders, active substances,

- Chemical industry: e.g., pigments, resins, detergents,

- Plastics processing: e.g., granulates, powders,

- Construction industry: e.g., cement, lime, fly ash,

- Feed industry: feed and feed additives.

Examples of system components

- pressure feeders (overpressure chambers),

- distribution and check valves,

- steel or plastic pipelines,

- receiving tanks with filters,

- loading and unloading devices: rotary valves, butterfly valves, dispensers,

- quality control (e.g., metal detectors, sieves)

- automation and safety systems.

Do ściągnięcia:

Do you need a pneumatic transport system?

Contact us and our engineers will prepare an optimal solution tailored to your process. We also offer audits of existing installations and modernisation of older transport systems.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7