- InterProcess Sp. z o.o.

Belt scales

If you want to weigh moving bulk material on a belt conveyor, belt scales are usually the best solution. It does not matter what material you transport or what type of industry you represent. Just send us the details of your transport system, the material being transported, and the required measurement accuracy, and we will select and propose the right solution.

Belt scales are installed on a conveyor belt. They are used to continuously measure the flow of material on the conveyor belt.

Belt scales can be used for:

- KControlling the flow and consumption of materials during production.

- Controlling mixtures.

- Checking dosing during loading and unloading of goods.

- Controlling the technological process.

We manufacture proven belt scale designs, ready for installation on customers’ conveyors. An important aspect is that for non-standard systems, we supply devices that are modified or designed specifically for the existing installation conditions.

Oferta

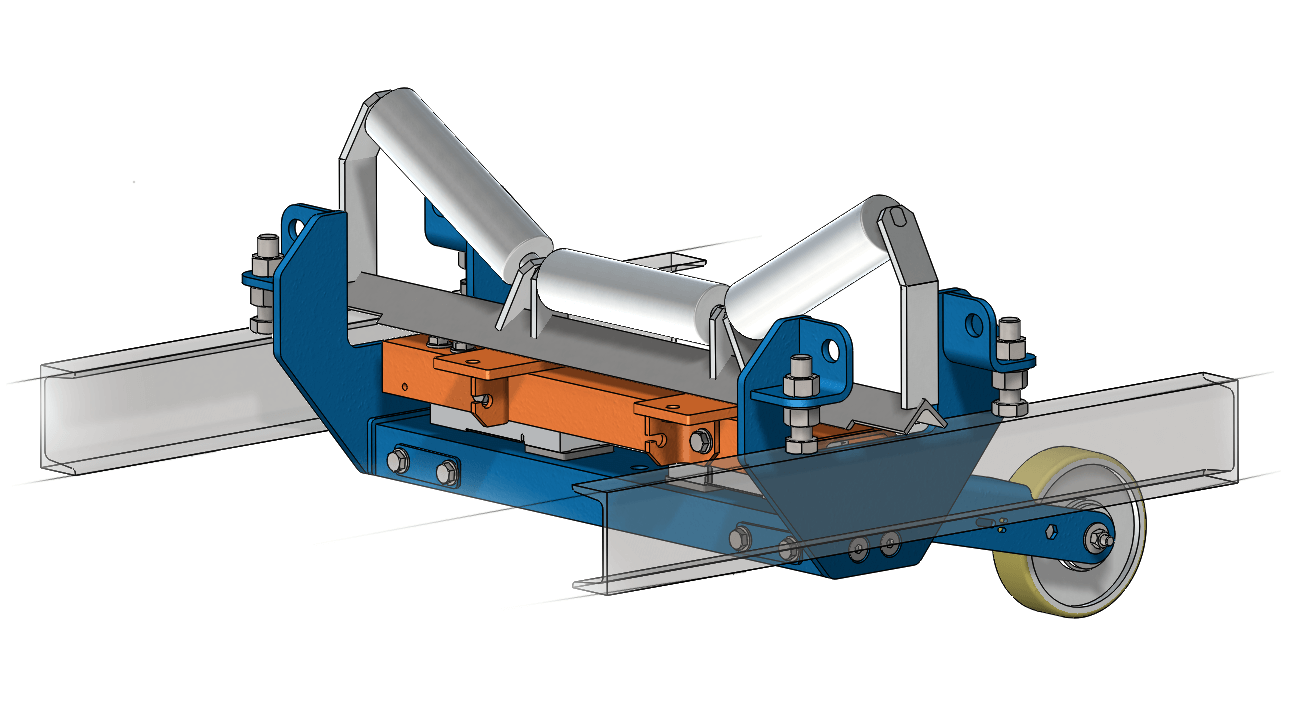

Belt scales, model WPL

The WPL model is the smallest and most affordable conveyor scale in our offer. Thanks to its small dimensions, it is perfect for situations where space is limited, e.g., on mobile crushers. Despite its small size, the conveyor scale’s construction is very rigid even under heavy loads, and the shielded strain gauge sensors are not exposed to damage.

Specification:

- The most affordable conveyor scale on the market.

- Two strain gauge sensors made of aluminum with IP67 protection.

- Measurement error ±0.5-2%.

- Possibility of adjusting the scale level.

- Belt width up to 1,200 [mm].

- Maximum flow up to 4,000 [t/h].

Download:

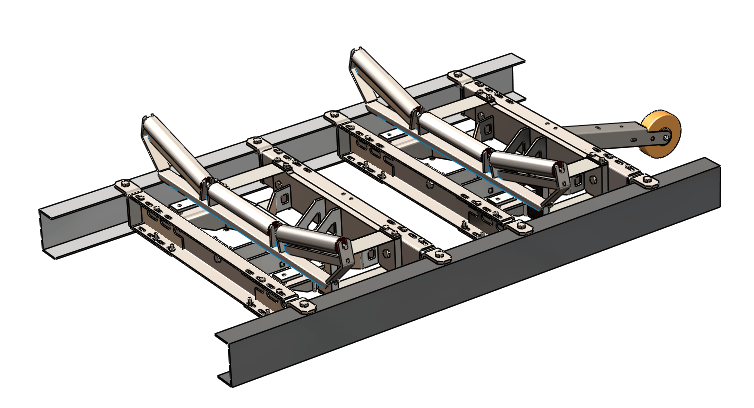

Belt scales, model WPC2

Extending the section on which the material is weighed usually allows for even greater accuracy. The material then remains on the conveyor scale for longer and can be weighed more accurately. WPC2 is actually two or more WPC1 scales, so all the advantages of this design also apply in this case.

Specification:

- Two or more WPC1 scales placed in series.

- Even higher accuracy: measurement error below ±0.25%.

- Rigid and reliable design based on a parallelogram frame with flat springs.

- No levers or pivots.

- Possibility of adjusting the level of the rollers.

- Wide range of belt widths: from 500 to 2,000 [mm].

- Maximum flow rate up to 12,000 [t/h].

- Strain gauge sensor made of stainless steel with IP68 protection.

Download:

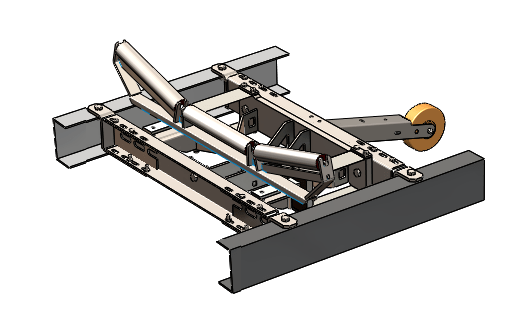

Belt scales, model WPC1

WPC1 is the conveyor scale most often recommended to our customers. It is used in the largest number of applications, and its design allows for the highest accuracy. The design itself was created after analyzing the dynamic requirements placed on weighing systems in systems characterized by very high loads. By using a single stainless steel sensor with an IP68/69K rating, we can minimize the risk of potential failure. The use of telescopic arms ensures that the scale will fit your conveyor perfectly.

Specification:

- Rigid and reliable construction based on a parallelogram frame with flat springs.

- No levers or pivots.

- Measurement error below ±0.5%.

- Possibility of adjusting the level of the rollers.

- Wide range of belt widths: from 500 to 2,000 [mm],

- Maximum flow up to 12,000 [t/h].

- Strain gauge sensor made of stainless steel with IP68 protection.

Download:

Principle of operation

A typical belt conveyor scale consists of a measuring bridge mounted on strain gauge sensors, an electronic measuring device, and a belt speed sensor. The strain gauge sensors determine the weight of the material on the belt. This information, in the form of a voltage signal, is interpreted by the electronic measuring device. Along with the weight, the device also reads the speed in the form of pulses from the belt speed sensor. Based on these two measured values, the mass flow rate on the belt [kg/s, t/h] and the counter increment [kg, t] are calculated.

You don’t have to worry about not being able to install and start up the device correctly. Our engineering team will take care of the installation, commissioning, and calibration of the scale on site. If your conveyor is unusual and a universal design cannot be used, we will design a belt conveyor scale specifically for you.

Our measurement electronics allow for much more than just weighing the flowing material. If your application requires it, we can equip the scale with flow control, portioning, or production line control functions. For each of our scales, we can issue a calibration certificate with calculated measurement uncertainty.

Do you need a conveyor scale?

Contact us and our engineers will prepare the optimal solution tailored to your process. We offer analysis and technical advice on the design of a suitable belt conveyor for flow weighing.

Why choose our solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7