- InterProcess Sp. z o.o.

Weigh belt feeders

Gravimetric weigh belt feeders are used for controlled feeding of material in batch and continous mode. They can also be used only to sum the flowing material.

Typical belt conveyors equipped with flow scales are often too large or unprepared to achieve high accurancy in long- term use and changing ambient conditions. Bearing in mind that the accurancy of dosing is ussualy associated with lower losses in material or higher quality of the final mixture, we have created special compact designs of DTU and DTC belt feeders.

Our devices are equipped with:

- weighing devices built on a basis od C3/IP68 load cells made entirely of stainless steel.

- with sensors detecting their swerve and slippage, and,

- internal and external scrapers that thoroughly clean them from the adhering material,

- gravity pulls providing a constant tensioning force of the belt,

- stripping system that mechanically help to keep the tapes in the axis of the device.

- control systems with volumetric and gravimetric operation functions, HMI and communication via various industial protocols.

Depending on the type of material, hoopers (also for aerated materials) or separate devices fixing the layer on the tape are selected.

Our offer includes two types of weigh belt feeders ranging from 20 [kg/h] to 1000 [t/h]. The most compact solution for light and medium-heavy materials is DTU weigh belt feeder. Constructed entirely od stainless steel in a way that facilities cleaning is the most often used in industry such as food, chemical, cosmetic etc. DTC weigh belt feeder is prepared to work with materials with high bulk density and very difficult working conditions, for example in the cement, lime and building materials industries.

Offer

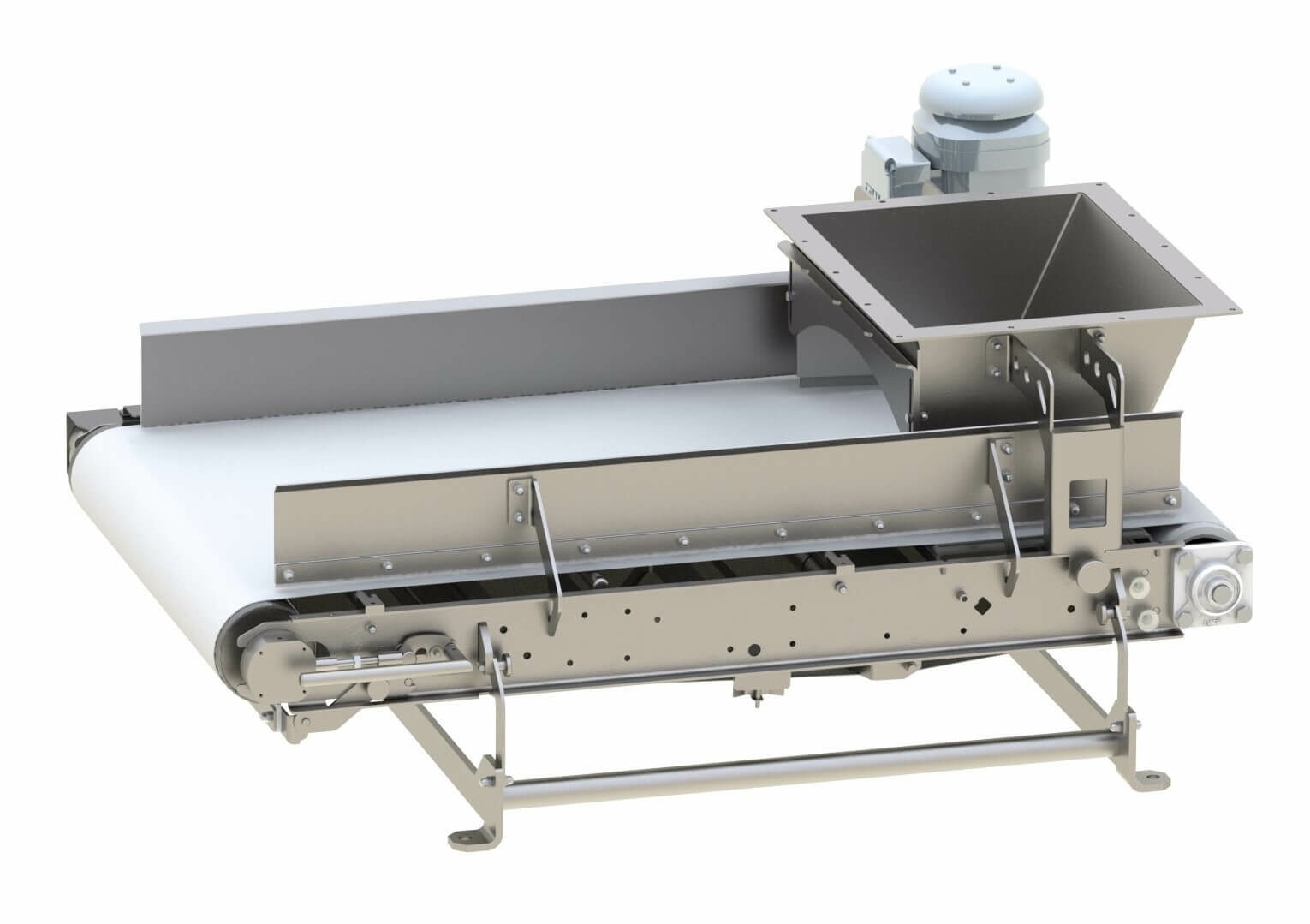

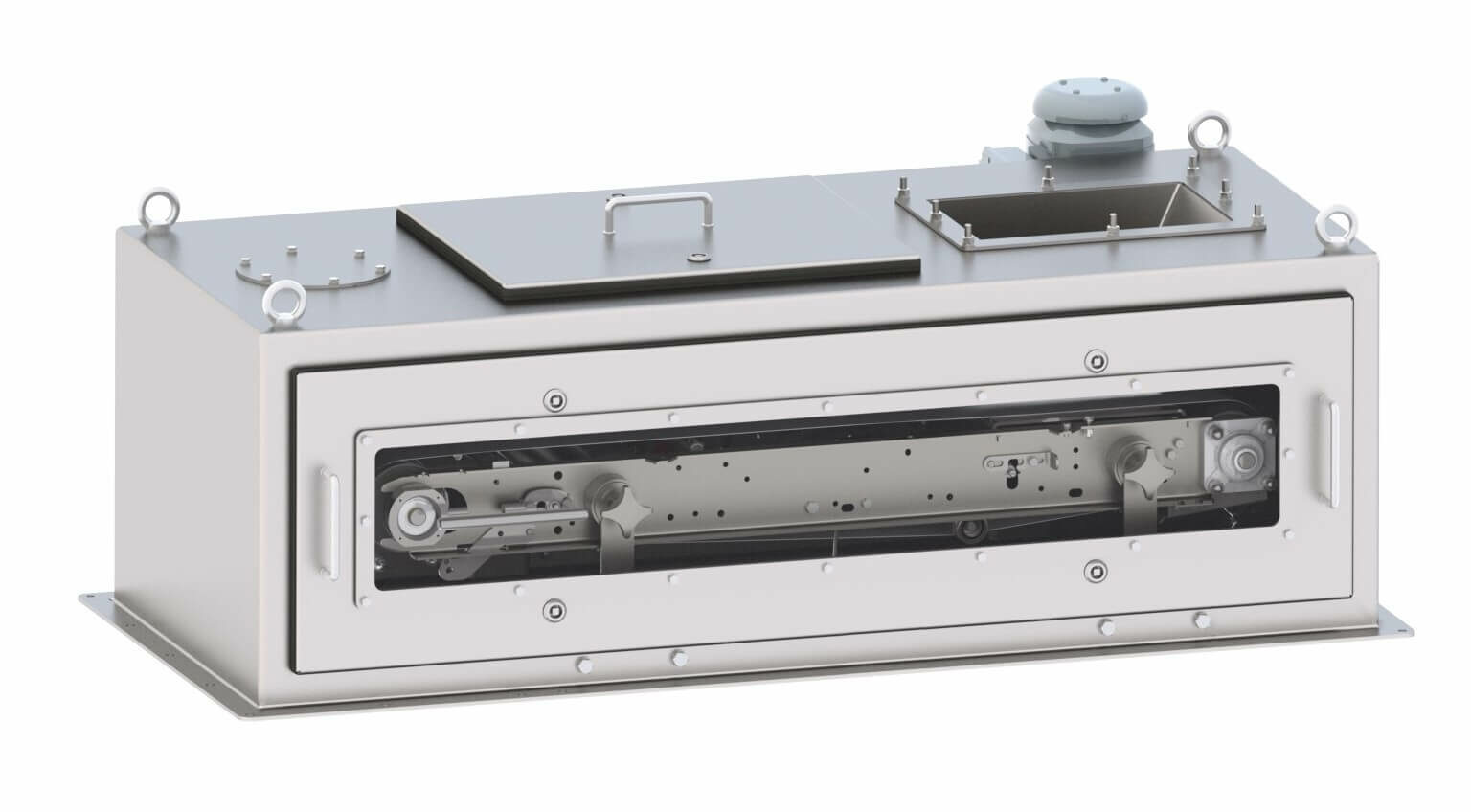

DTU weigh belt feeder

The DTU belt weighfeeder is a unique solution in our offer. Due to its high precision, it finds a particular application in feeding delicate products or in low and medium bulk density. In particular, thanks to the hygienic construction, which allows for an extremely easy cleaning, and the manufacture of fully certified materials and stainless steel is suitable for the food industry. Its uniqueness lies in compact dimensions and very high accuracy. The built-in scale, depending on the control system, allows dosing in batch mode or continuous mode, it can also only be used to measure flowing material. The feeder can be both in the open and closed version – in a dust-proof housing.

Applications:

- relatively well- or medium-flowing materials with fine grain size, low and medium bulk density, powders, granules or pellets. Perfect for fragile products that may be damaged during feeding. Perfect for the food industry.

Specification:

- measurement error <0,5% (in selected cases <0,25%),

- feed rates from 20 to 40 000 [l/h],

- belt width: 300 or 600 [mm],

- made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L),

- polyurethane belt with FDA approval in size 300 and 600 [mm],

- dustproof housing or open version,

- gravity belt take-up,

- internal and external scrapers,

- belt deviation control,

- quick belt change system.

Download:

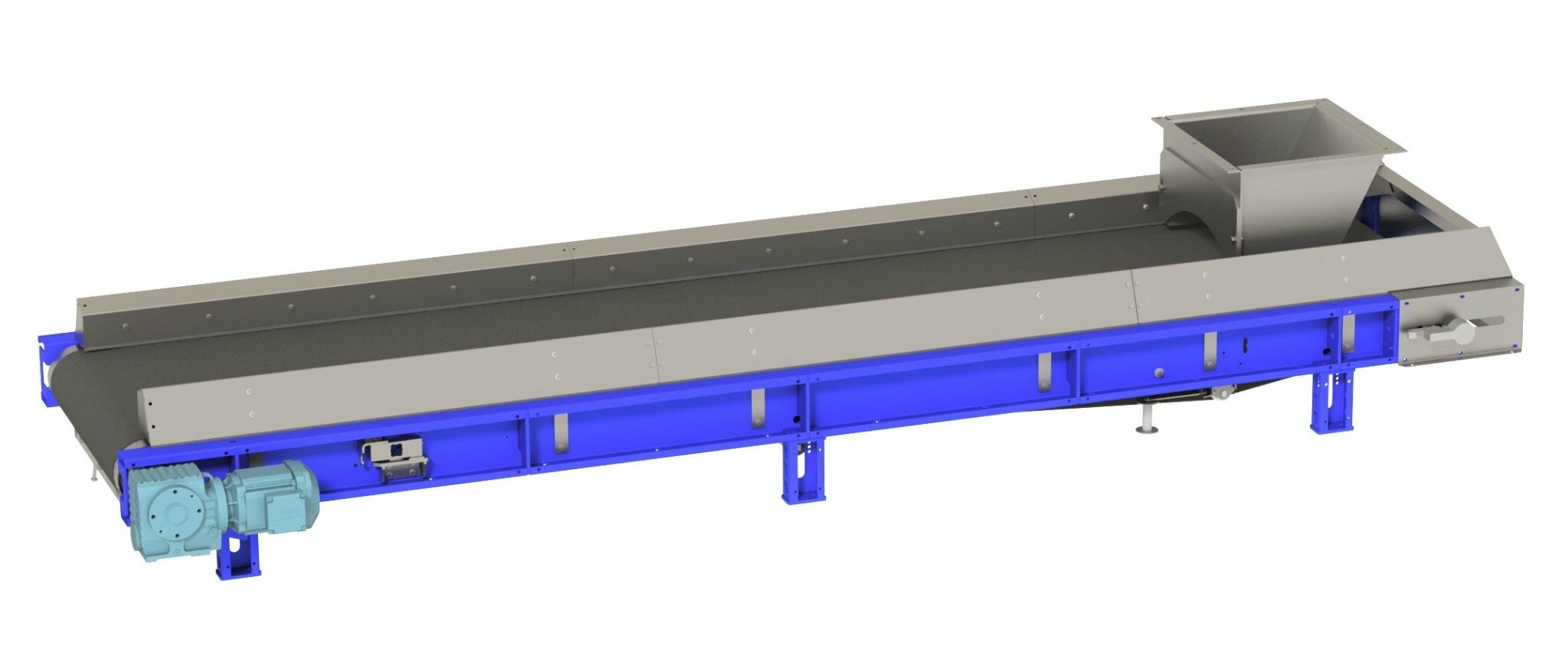

DTC weigh belt feeder

The DTC belt weighfeeder is the most versatile solution for feeding bulk materials with medium and high bulk density. The device has been designed to work in the most difficult conditions, in particular in heavy industry. High quality workmanship and durable materials allow for long-term and trouble-free operation, while ensuring the required accuracy of dosing. The feeder is made in terms of customer requirements, with different overall dimensions. Various variants of charging hoopers allow for proper work on theoretically difficult to feed materials – strong abrasive, aerating, flowing or pounding. An additional mechanism counteracting the belt’s deviation will reduce the risk of its damage, and the constant weight guaranteed by the gravity take-up will significantly extend its life and increase the accuracy of the measurement.

Applications:

- hard-flowing materials, highly abrasive, easily aerated with a tendency to uncontrolled flow. Perfect for working in difficult conditions.

Specification:

- rigid construction made of painted carbon steel, powder coated (on request also stainless steel),

- feed rates from 1 to 1000 [t/h],

- belt width: 650, 800, 1000, 1200 or 1400 [mm],

- end roller spacing: from 1500 to 8000 [mm] (every 500 [mm]),

- measurement error ±0,5%,

- the option of installing a legal-for-trade belt scales (OIML class 1),

- belts made of rubber or plastic, PVC, as well as with side flounces,

- additional belt gravity take-up system,

- belt deviation control,

- internal and external scrapers,

- feeding bulk materials in the range of 10-100% of the set value,

- various designs of charging hoppers adapted to the characteristics of loose material, also for easily aerated materials, with a tendency to uncontrolled flow,

- the possibility of using hard-wearing materials to protect elements particularly exposed to abrasion,

- Penko or Siemens control system allows you to handle both a single dosing line and to create a mixing node according to given recipes (e.g. fertilizer mixing lines).

Download:

Control systems

FLEX 2100 with BLT software

For belt weighfeeders, we offer the Flex 2100 (or Flex) controller, which is equipped with a touch screen with process visualization, special software created by us in Polish and extensive communication capabilities (RS232 / 422, Ethernet, Profibus, Canbus). The driver enables, among others control of belt slip, reading from sensors – speed and weight, selection of gravimetric and volumetric mode, control of material feeding speed by means of so-called prefeeder (device fixing the layer of material on the scale) and a preview of 3 dosing counters. The software can also be modified to control the remaining elements on the production line.

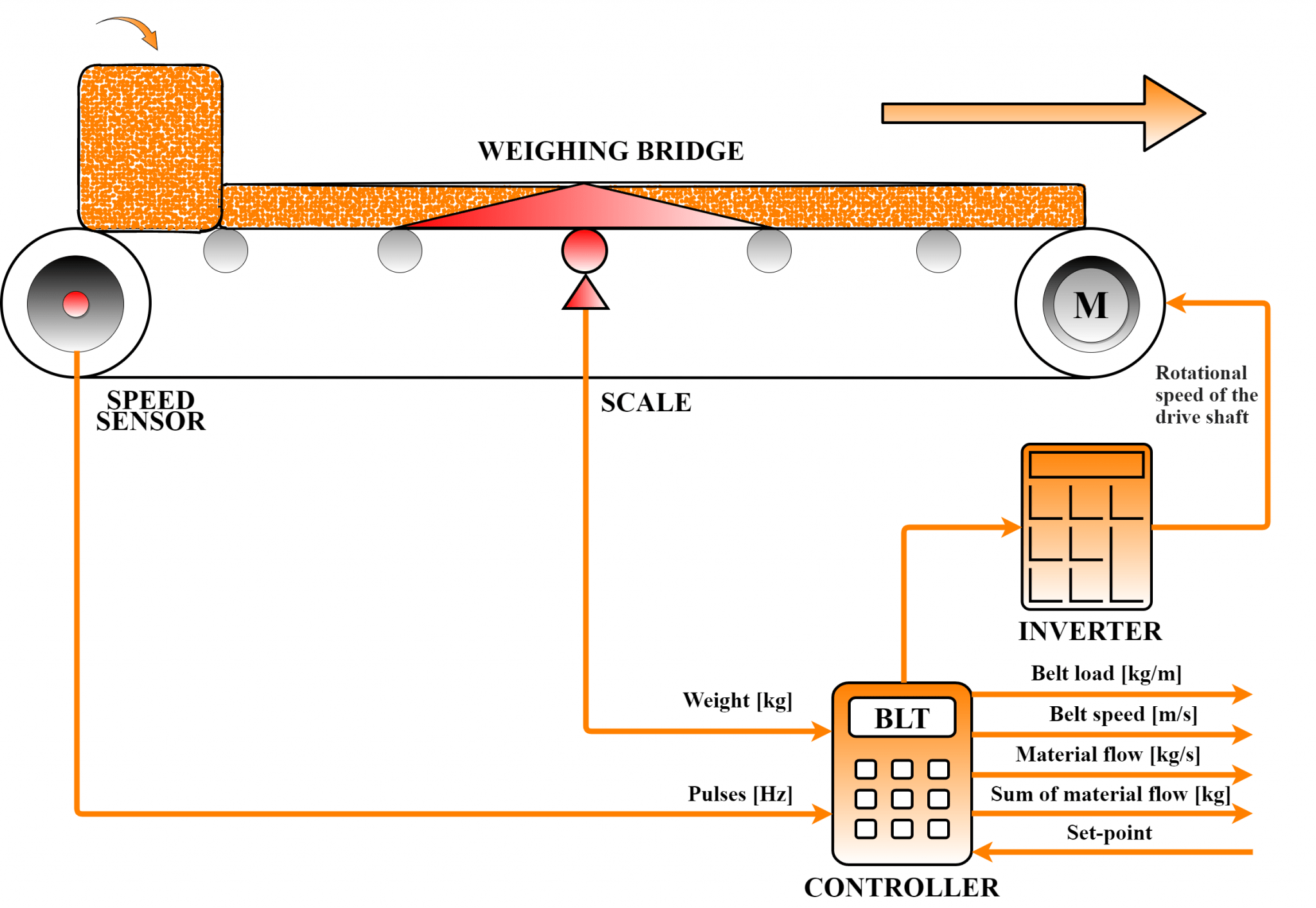

How does it work?

The belt weighfeeder is a conveyor whose construction has been designed primarily to measure the flow of bulk material. This means that not only does it have a built-in belt scale, but all of its elements are made extremely precisely. For proper operation, the control system needs signals: belt speed and material mass on a precisely defined belt segment. It is then about continuous dosing, with the regulation of material flow. Dosing can be done in two ways: by feeding a fixed layer of material at an adjustable speed, where the material layer is formed by the outlet of the hopper – the so-called a layer or by means of adjustable material feeding on a weighing conveyor through a preceding device (pre-feeder). In the basic application, the material can be fed with the speed set by the operator, but after activating the PID control option, the weighing controller gains the ability to determine the speed of the belt or feeding device to the desired flow.

Construction

The belt feeders consist of a belt conveyor with a built-in scale together with the control electronics. The high quality of materials used to build our feeders makes them suitable for use even in the most challenging conditions, where expectations for failure-free operation are greatest. Each of our feeders has a strictly defined length of the weighbridge. Thanks to this, the weighing controller collects information about the weight of material only from a particular section of the belt, and there is no need to weigh the entire feeder, which significantly increases the accuracy of the measurement. Also, the modern designs of weight feeders that we offer consist of several systems that help you maintain, improve efficiency and extend its life. The use of pulses with a large number of pulses allows the speed to be read even at low rates and the feeder reacts quickly to changing feed, changes in the physicochemical properties of the material or a temporary lack of it. The belt guiding systems and gravity tension guarantee longer work without the need for correction in the tension and minimize weight errors associated with changes in the characteristics of transmission belts under the influence of the environment or wear. Depending on the requirements for flow, material or type of industry, we select the type of feeder, width, and length of the belt and the type of hopper. For applications with increased production cleanliness, we recommend dustproof covers or cases.