- InterProcess Sp. z o.o.

We specialize in designing and supplying complete process lines for handling bulk materials. We offer comprehensive support – from design and equipment selection to system commissioning. Our installations are used in the food, chemical, and pharmaceutical industries, among others.

The use of special transport bags called BIG-BAGs is very popular in industry for handling bulk materials. Our designs enable efficient and dust-free filling or emptying of bags with minimal employee involvement.

We provide our customers with solutions that make the transfer of dry bulk materials, such as powders and granules, more efficient and effective. This solution is easy to keep clean, minimizes maintenance, and eliminates dust, especially in Ex zones.

We design and supply our customers with ready-made weighing systems. Our systems can count material on a conveyor belt and regulate flow. We also offer ready-made belt feeders with built-in scales, characterized by very high dosing accuracy.

We are a manufacturer of high-quality dispensers for bulk materials. Whether it is a batch or continuous process, our devices are suitable for feeding even difficult and demanding products. The need to work in Ex zones is not a problem for us.

One of the typical applications of our devices is all kinds of filling systems. This applies to various types of packaging, especially packaged goods weighing less than 50 kg. We are able to carry out this process safely, efficiently, and dust-free..

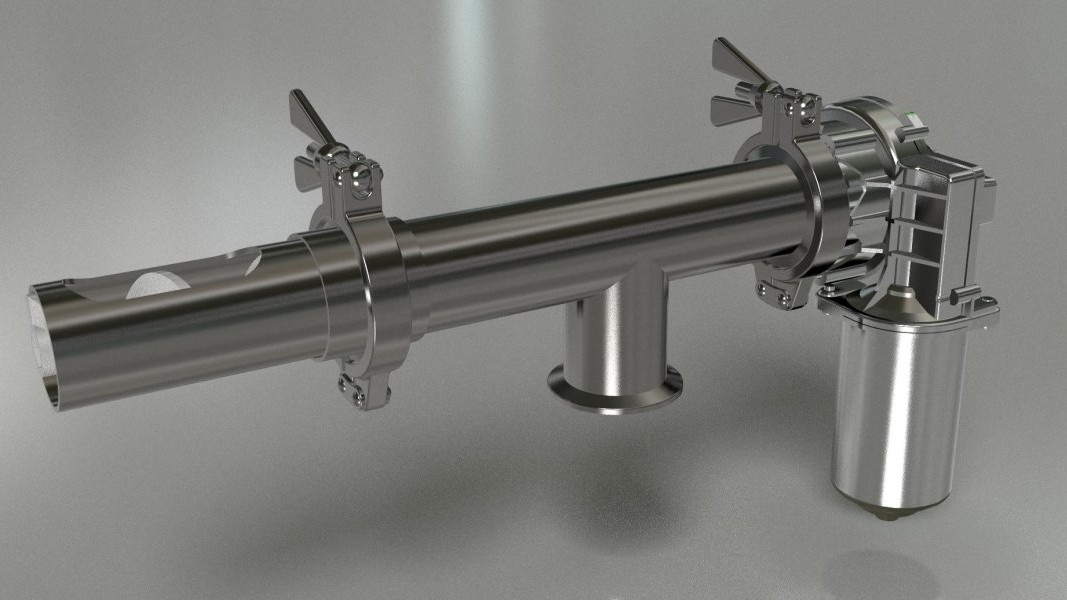

Sampling is a key stage in the quality control process in industry, allowing the conformity of a product with requirements to be assessed. In many industries, sampling procedures are strictly defined by standards. The safety and effectiveness of the final product often depends on the quality of the sample.

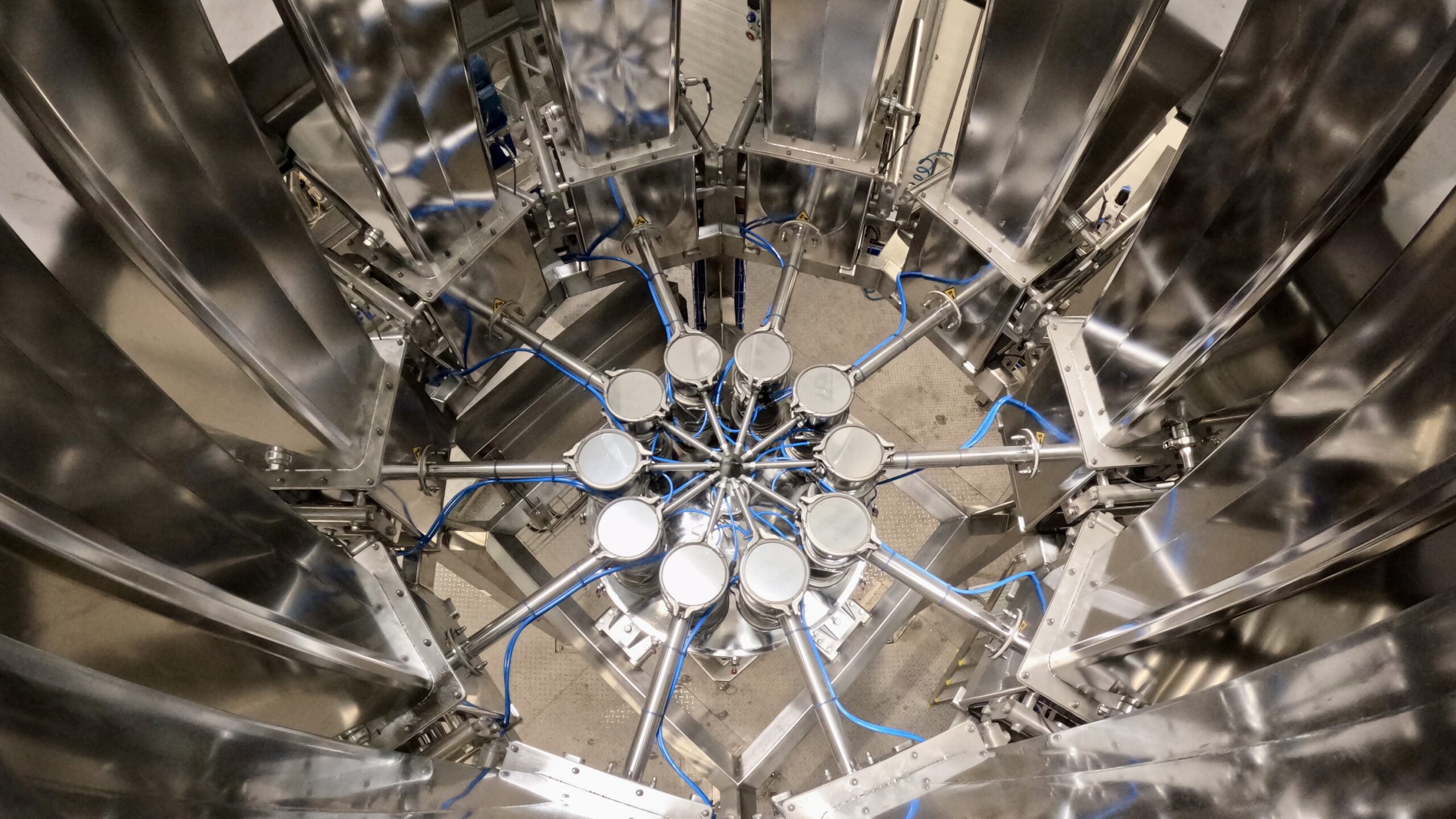

Our solutions enable the creation of dosing nodes that are used to prepare highly accurate mixtures. Whether it is upstream of a mixer, reactor, or packaging machine, high dosing precision translates into final product quality and cost optimization.

The grinding of bulk materials, granulation, and particle size reduction are key processes in many industries. The right choice of technology not only increases efficiency but also prevents blockages and improves the quality of the final product.