- InterProcess Sp. z o.o.

Whether you are interested in dispensing a fixed portion of material or your process requires a constant flow, we have the solution for you

Gravimetric screw feeders, operating in loss-in-weight mode, are the most versatile solution for feeding most bulk products in the flow range of 0.5 to 30,000 [l/h].

The first step is to define the material parameters, such as: grain size, bulk density, moisture content, angle of repose, required flow rate, and portion in the desired time interval (if batch dosing). Based on the information provided by you, we select the type and equipment of the feeder depending on the type of material. The material is fed by a dosing element in the form of a solid screw or spiral (helix). Its correct selection must be carefully carried out by us, based on the characteristics of the bulk product, tests carried out, and our experience.

Gravimetric screw feeders are also equipped with one or two agitators that ensure stable material flow inside the feeder. High accuracy is guaranteed by a precise weighing system consisting of a rigid support structure on which two or three C3 class strain gauge sensors are mounted. The sensors are made of stainless steel and have an IP68/IP69K protection rating, making them ideal for even the most demanding working environments and ensuring a long service life. Each scale is mechanically protected against overload and has ready-to-install transport/service locks. For particularly demanding customers in the food, cosmetics, or pharmaceutical industries, we offer devices in a special hygienic version.

Offer

DSL(35-75-150) G

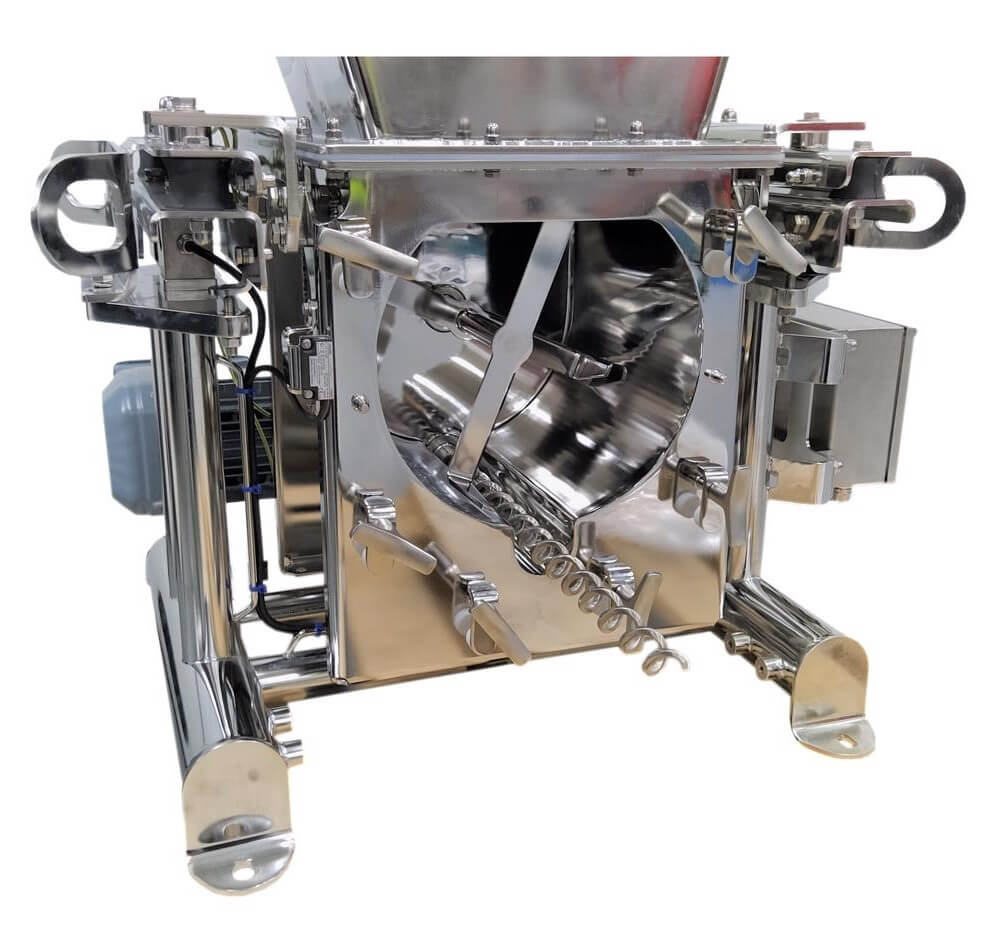

The DSL G gravimetric screw feeder can feed bulk materials with different parameters, even those that are difficult to flow and tend to clump and stick. It is a universal device for both continuous and batch feeding.

The dispenser consists of a main chamber, a horizontal agitator, a precision strain gauge scale, and a hopper. It generates material flow thanks to a rotating screw, assisted by a horizontal agitator, which ensures that the dispensing element is completely filled and prevents the material from sticking. Typical hoppers with the appropriate wall geometry enable reliable flow of the dosed materials. The DSL G dispenser can be equipped with dosing elements in the form of a solid screw (with a guide pin) and a spiral (dosing screw without a guide pin). This makes it ideal for applications where extreme materials must be fed, ranging from dusts with a grain size of a few micrometers to large granules and pellets.

Intended use:

- dry bulk materials of virtually any type – both free-flowing and difficult-to-flow, easily aerated, with a tendency to flow uncontrollably or clump together.

Features::

- dosing error in continuous mode typically <0.5% of the set value, in batch mode depending on the range of strain gauge sensors,

- capacity from 0.5 to 30,000 [kg/h], with a min/max operating range of a single device = 1/10,

- dosing elements (screws, spirals) with diameters from 18 to 150 [mm],

- agitator (mixer) prevents clogging and bridging of loose products,

- elements in contact with the material made of stainless steel 1.4301 (AISI304) or 1.4404 (AISI316L), others powder coated (support frame),

- finish: glass bead blasting or electropolishing,

- optional hygienic design: continuous internal and external welds, surfaces in contact with the material ground (Ra<0.8), ground welds, special design.

Specification:

- the most affordable conveyor scale on the market,

- two strain gauge sensors made of aluminum with IP67 protection,

- measurement error ±0.5..2%,

- possibility of adjusting the scale level,

- belt width up to 1,200 [mm],

- maximum flow rate up to 4,000 [t/h].

Do ściągnięcia:

Hygienic version according to EHEDG

Even in their standard version, our dispensers are suitable for use in the food industry. The materials used that come into contact with loose products are FDA-approved or made of stainless/acid-resistant steel.

For more demanding customers, we offer a special hygienic version of our device in accordance with EHEDG recommendations. In this case, the device has a different design, both in terms of the dispenser chamber and the support frame. Thanks to quick and safe access to the interior and a more open frame design, the device is extremely easy to clean inside. Both the dosing element and the agitator can be quickly dismantled for cleaning or replacement. 316L acid-resistant steel and an additionally ground interior and welds to a roughness of Ra<0.8µm ensure even greater production safety. The dispenser uses aseptic motors (not applicable to explosion-proof versions), which are easy to clean due to the absence of fins and a fan.

Feeders in explosion hazard zones

Explosion hazard zones are designated in many production facilities. Our dispensers can also be supplied with the appropriate certificate in an intrinsically safe design, in accordance with standards harmonized with the ATEX Directive. In such devices, appropriate components are used, and the continuity of equipotential bonding ensures the correct discharge of electrical charges.

Our engineers will be happy to advise you on how to install the dispenser in your production line so that it functions correctly and safely over many years of use.

Do you need a feeder?

Contact us and our engineers will prepare the optimal solution tailored to your process. We offer the possibility of testing your material on our device.

Why Choose Our Solutions?

Individual approach – we design each system to meet the customer’s needs.

Comprehensive implementation – from design to commissioning and service.

Proven components – only reliable, industrial solutions.

Experience in many industries – food, chemical, pharmaceutical, construction.

Safety and hygiene – systems compliant with ATEX, HACCP, and GMP standards

Technical support and service – with quick response, also available 24/7