- Ku Wiśle 7, 00-707 Warsaw

- +48 787 783 590

- biuro@interprocess.pl

Weighing and dosing on belt scales and weight belt feeders

Belt scales

Belt scales are installed on a conveyor belt. They are used to measure the flow of material on a conveyor belt continuously.

Belt scales can be used for:

We produce proven bet scale constructions, ready for installation on customers’ conveyors. An important aspect is the fact that in the case of non-standard systems, we deliver devices modified or designed specifically for the existing building conditions.

Over the years of the company’s operation, we have provided solutions for customers from various industries, primarily: coal, aggregate processing, food, feed production and others.

Weight belt feeders

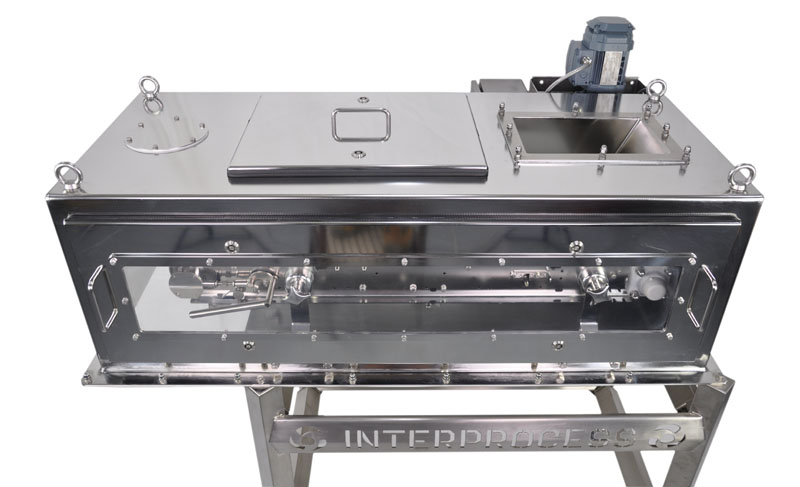

Weight belt feeders are modern steel-based devices.

Belt dispensers are modern devices with a steel structure.

They are used for smooth and even feeding of solid and powdery materials.

Weight belt feeders can not only dispense material, but also control its flow, taking into account factors such as belt speed and material weight.

Weight belt feeders can be used for:

Weight belt feeders are used in the cement, construction, chemical, mining and food industries.

Control systems

If you already have a belt scales with a weight installed, we suggest our control systems. These are some of the most advanced solutions on the market. They feature a friendly interface, rich communication options and exceptional speed.