- ul. Ku Wiśle 7, 00-707 Warszawa

- +48 787 783 590

- biuro@interprocess.pl

Stacje rozładunku worków STB to świetne rozwiązanie, gdy do procesu muszą być podawane niewielkie ilości materiałów.

Urządzenia przeznaczone jest dla produktów sypkich, które dostarczane są w workach o pojemności najczęściej do 50 litrów. Zapewniają wygodny sposób opróżniania i podawania niewielkich ilości produktu do głównego procesu – np. do mieszalnika lub systemu transportu pomiędzy dwoma odległymi punktami instalacji procesowej. Stanowią bezpieczne rozwiązanie, które pomaga uniknąć urazów kręgosłupa i zminimalizować pylenie.

Dzięki modułowej konstrukcji mogą być wyposażona w szereg urządzeń dodatkowych takich jak. m.in. kompaktor worków, magnes ziem rzadkich, zawór celkowy, zespół ssania oddolnego czy dozownik śrubowy.

Zabudowany wentylator wyciągowy wraz z systemem filtrów, z funkcją automatycznego czyszczenia pomagają w utrzymaniu czystości w obrębie urządzeń.

Oferta

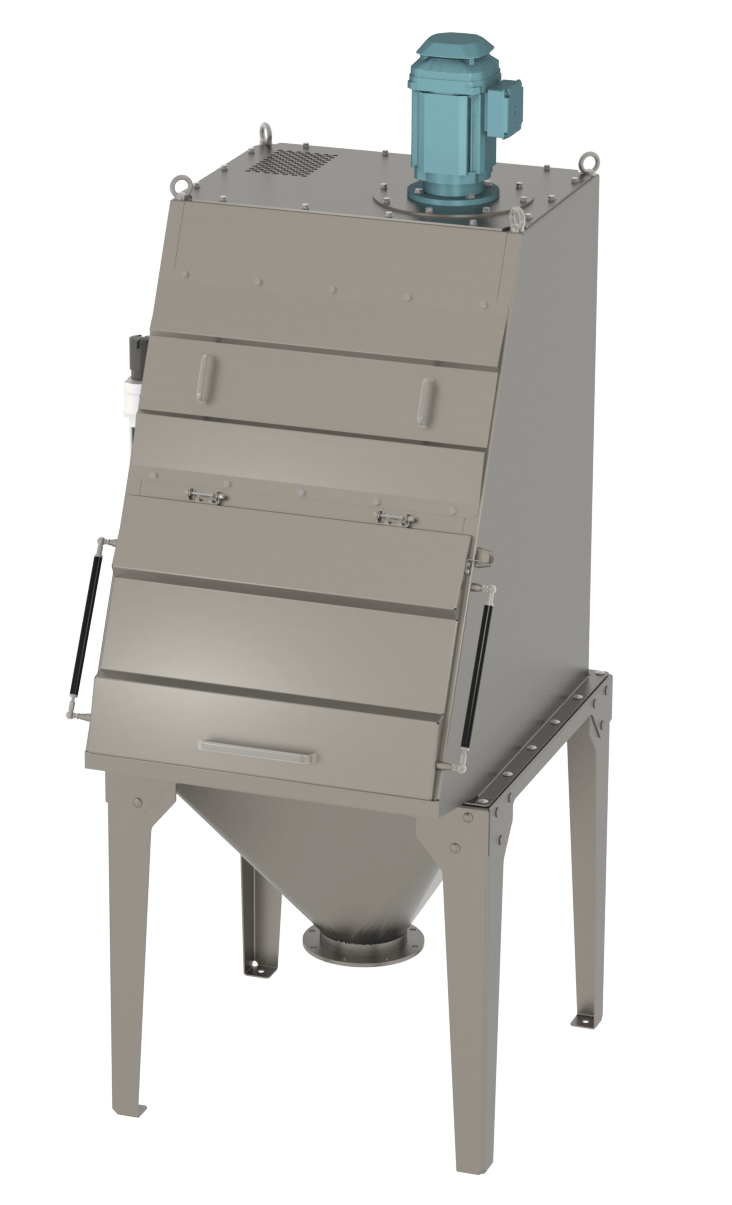

STB-V1 – stacja ręcznego opróżniania worków

Specyfikacja:

- wentylator wyciągowy SEW 1,1 kW 3×400/3×500 VAC,

- filtry patronowe (kartridżowe) o powierzchni 8-12m2,

- czyszczenie filtrów automatyczne, przy użyciu wbudowanego sterownika i sprężonego powietrza 6 bar,

- wygodny blat ułatwiający ułożenie worka oraz kratka zasypowa (dla bezpiecznego rozładunku),

- klapa dostępowa wyposażona w sprężyny gazowe oraz czujnik położenia uruchamiający wentylator wyciągowy lub sekwencyjne czyszczenie filtrów.

Wykonanie:

- stal nierdzewna 304 (szkiełkowana lub elektropolerowana),

- stal kwasoodporna 316L (szkiełkowana lub elektropolerowana).

Przeznaczenie:

- różnego rodzaju pylące materiały sypkie, np. drobnoziarniste i gruboziarniste proszki, ziarna, granulaty

Do ściągnięcia:

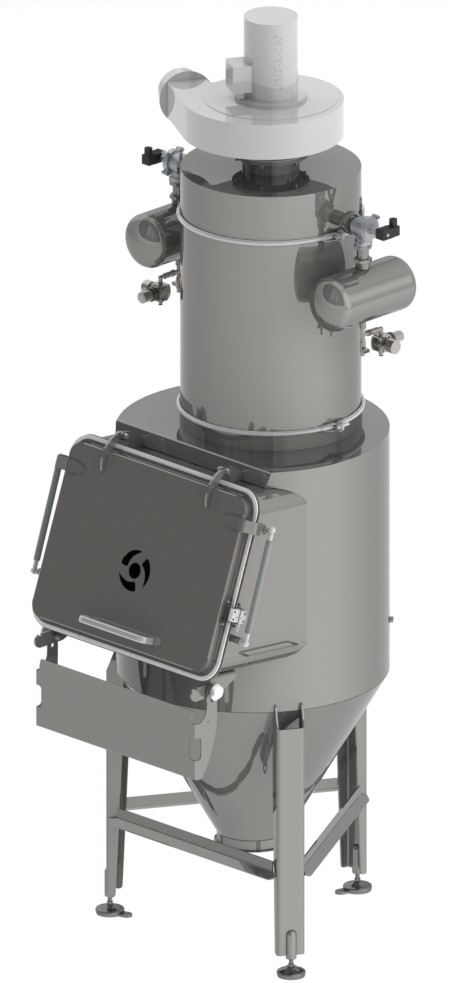

STB-V2 – stacja ręcznego opróżniania małych worków

Specyfikacja:

- wentylator wyciągowy 0,75 kW

3×400 VAC, - filtry patronowe (kartridżowe) o powierzchni 8m2,

- czyszczenie filtrów automatyczne, przy użyciu wbudowanego sterownika i sprężonego powietrza 6 bar,

- wygodny blat ułatwiający ułożenie worka oraz kratka zasypowa (dla bezpiecznego rozładunku),

- klapa dostępowa wyposażona w sprężyny gazowe oraz czujnik położenia uruchamiający wentylator wyciągowy lub sekwencyjne czyszczenie filtrów.

Wykonanie:

- stal nierdzewna 304 (szkiełkowana lub elektropolerowana),

- stal kwasoodporna 316L (szkiełkowana lub elektropolerowana).

Przeznaczenie:

- różnego rodzaju pylące materiały sypkie, np. drobnoziarniste i gruboziarniste proszki, ziarna, granulaty

Do ściągnięcia:

Opcje

- Stacja z zabudowanym wentylatorem

- Stacja bez zabudowanego wentylatora, z wykorzystaniem zewnętrznego systemu odpylania

- Kompaktor pustych worków

- Magnes ziem rzadkich

- Wykonanie ATEX dla stref 21 i 22.

- Urządzenia wspomagające rozładunek:

– grzybki wibracyjne

– wibrator

Dolna część stacji może być przeznaczona do współpracy z:

- dozownikiem śrubowym

- zaworem celkowym

- zespołem ssania oddolnego

- przepustnicą motylkową lub zasuwą nożową

- lancą ssawną

- sitem wibracyjnym

Sposób użycia stacji

Krok 1: operator otwiera klapę dostępową, która uruchamia wentylator wyciągowy.

Krok 2: umieszcza worek na blacie stacji znajdującym się wewnątrz stacji, następnie rozcina go i wysypuje zawartość bezpośrednio do zbiornika stacji (lub urządzenia poniżej). Przepływ powietrza generowany przez wentylator wyciągowy powoduje, że pył unoszący się z wysypywanego materiału jest wciągany do środka stacji.

Krok 3: zapylone powietrze filtrowane jest przez wkłady patronowe znajdujące się wewnątrz stacji. Po wykonanym rozładunku operator zamyka klapę dostępową. Osadzony na powierzchni filtrów pył jest zdmuchiwany przez pracujące sekwencyjnie dysze ze sprężonym powietrzem. Automatyczne czyszczenie filtrów obywa się, tylko gdy pokrywa jest zamknięta, a wentylator nie pracuje, aby nie stwarzać dodatkowego zapylenia podczas rozładunku.